A modular system for data capture without part preparation

Fast, intuitive and highly precise

A modular all-in-one concept

Early detection of deviations

Software for a guided workflow

ZEISS INSPECT guides the operator through scanning, probing and inspecting and allows for real-time progress monitoring.

Optical tracking for small and large volumes

Combine a hand-held T-SCAN laser scanner with the optical tracking system of your choice: the established T-TRACK 20 for large measuring volumes of up to 20 m³ – or the T-TRACK 10 for a smaller measuring volume of up to 10 m³ and higher accuracy. If you want to quickly and reliably capture individual measuring positions, choose the touch probe T-POINT. It’s the perfect solution for single-point measurements on object areas such as trimmed edges and standard geometrics or optically hard-to-reach areas.

ZEISS INSPECT: Intuitive software for a simplified workflow

A wide range of applications

Quality control and inspection

- Nominal-actual CAD-to-part comparison

- Boundary edge extraction of sheet metal parts

- Inspection of complex welded structures

- Shop floor inspection

Tool and mold making

- Tool reconstruction

- Scan data for machining path generation

- Actual capture following tool approval

- Capture of complex component dynamics, e.g. during a clamping procedure

Product development and design

- High dynamic range to scan all kinds of surfaces

- Scanning of design models for CAD downstream processing and documentation

- Gage and fixture setup

- Fast capture of reference geometries and specified areas

Technical Data

Do you want to find out more?

Discover more

i

Please select the topic you seek more information aboutHow to scan difficult surfaces

Welcome behind the scenes at IndyCar racing team RLL. The task: to scan a windshield. The problem: the laser or projected fringe can penetrate the surface. The solution: a 3D scan spray to coat the surface – for a much cleaner STL-file that’s ready for inspection.

T-SCAN: Your first use of the hand-held 3D scanner

Discover how to scan an object with the hand-held T-SCAN laser scanner. First, verify the field of view and the correct stand-off distance of the scanner. Make the task extra easy by using a pre-defined scanning template. The software automatically aligns every scan.

Chapters

00:28 Field of view

00:47 Stand-off distance

01:15 Pre-defined scan templates

01:32 Scanning

02:06 Polygonize and recalculate

T-SCAN: Extend a measuring volume with surface best-fit

Extend the measuring volume of the optical tracker T-Track by using the surface best-fit feature in GOM Inspect Suite. After capturing the 3D scanning data, David shows you how to transform it in order to get a perfect digital twin with the T-SCAN system.

Chapters

00:27 Initial part orientation

01:00 New part orientation

01:20 Create new measurement series

01:55 Transform measurement series

02:32 Polygonize mesh

T-SCAN: Single-point measurements with the touch probe

Find out how to use the touch probe T-POINT in combination with the optical tracker T-TRACK to measure individual points or deep holes. Simply define the feature you want to probe in the software GOM Inspect Suite, then follow the guided workflow to take measurements.

Chapters

00:39 Button functions

01:20 Pre-define elements to measure

01:55 Guided workflow

02:14 Measure an element

02:34 Accept a measurement

T-SCAN: Extend the measurement volume with a touch probe

How do you scan areas that are hidden from the optical tracker? Learn to extend your measurement volume with the help of the touch probe T-POINT: Simply rotate the part between scans – and probe the same features (e.g. holes) in all positions as reference points.

Chapters

00:28 Use of magnetic cones

01:36 Switch mode to scan surfaces

02:23 New part position

02:32 Create additional measurement series

02:53 Measure magnetic cones in new position

03:56 Transform measurement series

T-SCAN: Get some useful tips & tricks

Get some tips & tricks from David for the precise T-SCAN system. Learn why the T-TRACK should always look down on the part you want to scan, how you should adapt the scanning speed to the feature you want to scan and how to find the right scanning parameters.

Chapters

00:29 How to orientate the T-TRACK

00:52 Adapt the scanning speed

01:29 Find the right scanning parameters

T-SCAN: Your first use of ZEISS INSPECT

Learn how to use ZEISS INSPECT with your T-SCAN system and watch David create a digital twin of a motorcycle frame. Just make sure the part you want to scan is inside the measurement volume of your optical tracker! Using the hand-held scanner is fast and intuitive.

All functions shown are available in the current software version.

Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

Chapters

00:28 Start screen of GOM Inspect

00:46 Initialize the sensor

01:07 Verify the part is inside the measurement volume

02:04 Start scanning

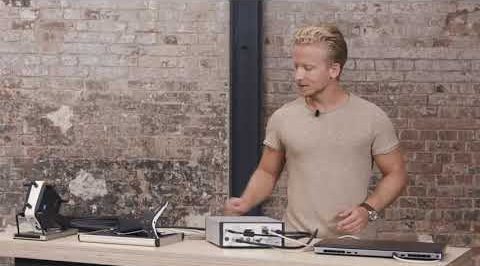

T-SCAN: How to set up your new laser scanner system

Mount the optical tracker on the tripod and connect the cables of all scanning components to the controller. Then connect the power cable and the laptop to the controller, plug in your license dongle, open the laptop, switch on the controller and start GOM Inspect Suite.

T-SCAN: The difference between T-SCAN 10 and T-SCAN 20

Discover the differences between the 3D scanning systems T-SCAN 10 and T-SCAN 20. First: T-SCAN 20 has a measurement volume of 20 m³, while T-SCAN 10 scans up to 10 m³. Second: T-SCAN 10 is accordingly cheaper. The good news: You can always upgrade.

Chapters

00:28 Measurement volume

00:48 Measurement depth

Discover our newest video sessions

Follow us

Sessions

Solutions

Digital Events

Subscribe to our newsletter

- Privacy Policy

- Imprint

- ©2023. All Rights Reserved