The work at the Museum of Cultural History

The Museum of Cultural History is a faculty of the University of Oslo. Thanks to their extensive expertise in the management, research and dissemination of cultural history, they are known as a leading institution for museum research in Norway. They display the largest archaeological and ethnographic collections covering a timespan from the Stone Age, the Viking Age, the Middle Ages, up to the recent times. The faculty’s Viking Ship House Museum opened its doors in 1926 and continues to attract history enthusiasts every year.

Complex 3D scanning projects

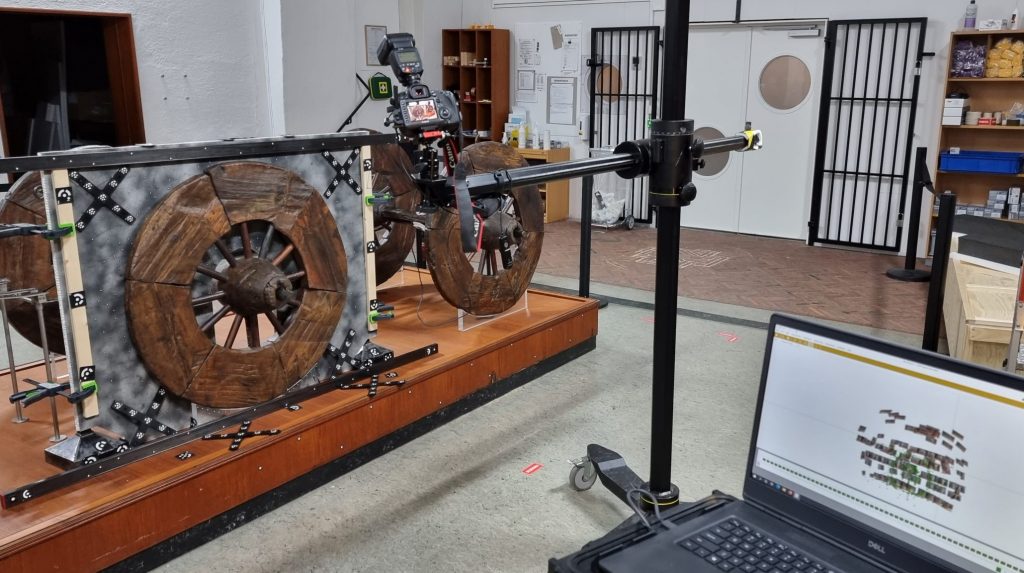

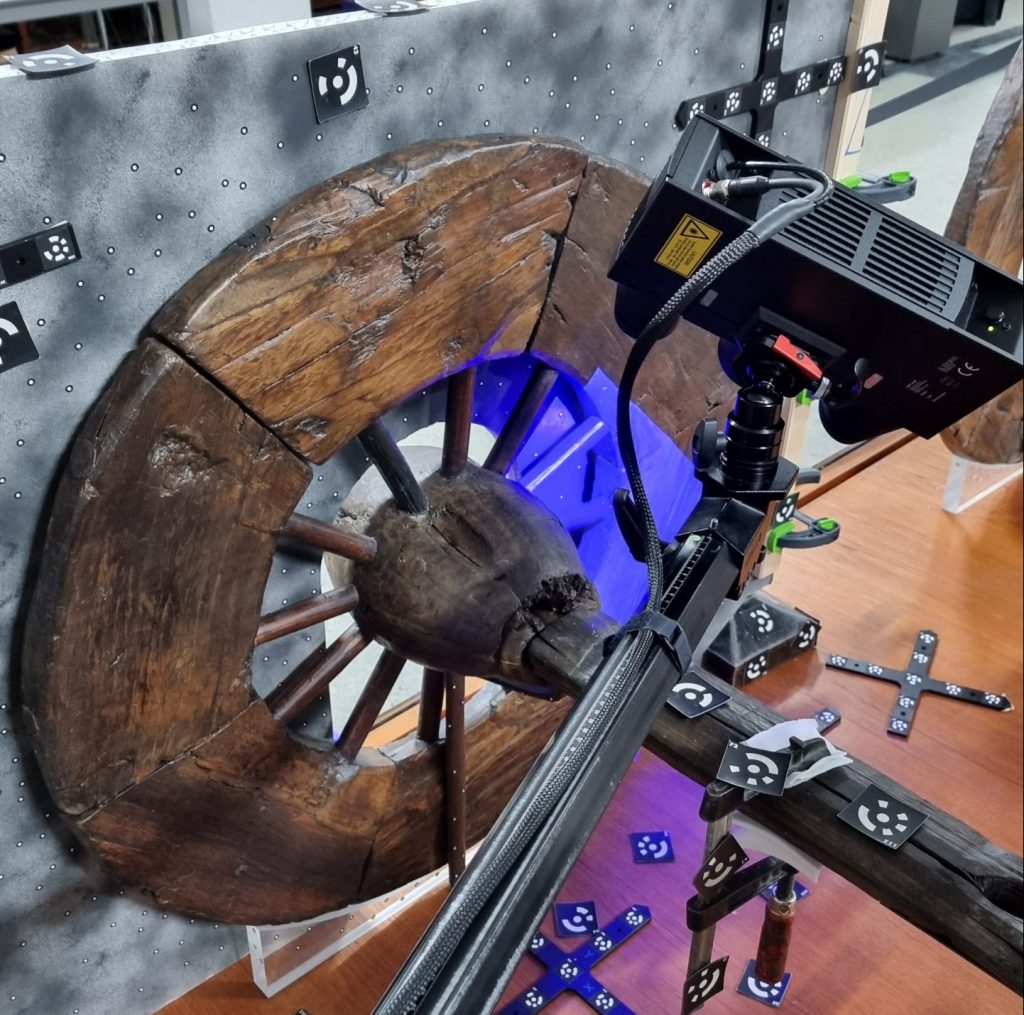

In one of the more complex projects, the wooden Oseberg Wagon was digitized. It is the only Viking wagon that still exists today. Since it was to be moved to new accommodation, the wagon had to be disassembled. Due to its unique carved ornaments and the increasing instability, the creation of a digital backup of this historical artifact was almost inevitable.

However, this project combines several challenges: The object to be scanned is 5.5 meters long, 1.5 meters wide and 1.2 meters high. The wagon is made of complex geometries and a surface, decorated with ornaments depicting various fine objects and symbols. During the disassembly of the wagon, each part was scanned with the ATOS Q MV270 + TRITOP to obtain a reference system and color of the surface.

After this was completed, the first model was converted into a CAD model. Based on this, the individual parts could be aligned with the model using the “Best Fit” function. This way the wagon was assembled digitally step-by step. This approach proved to be very successful. Thanks to the very powerful ZEISS Quality Suite, very precise assembly drawings for reassembly are now created.

Software insights

Take a look at how the collected 3D data performs in the software ZEISS INSPECT – from the photogrammetry images to the mesh and the final 3D models.

Advantages of modern, optical 3D scanners for restoring culture

3D scanners – especially the ATOS Q – is an integral part at the Norwegian museum. They have been using the modern measurement method since 2013. The accurate results achieved with the ATOS Q and the depth of detail of the 3D data, especially for difficult to inspect and intricate surfaces, are particularly decisive factors in the choice of the 3D scanning solution.

In addition, the optical 3D scanners enable contactless measurement of the objects. It should be mentioned here that the very old artifacts are very fragile and are often only held together by a thin layer of varnish. Non-contact and fast measurement is therefore highly relevant in order to avoid damaging the parts. If you look at the historical objects to be scanned, you will notice that they often have elaborate decorations. These are often made of metal rivets, such as iron, silver or even gold elements. These details reflect a lot of light, which makes accurate scanning difficult. After many tests at the museum with different scanners, the ATOS Q proved to be the best solution for these tasks.

Depending on the project, the ATOS Q with a measuring volume of 270 or 500 is selected.

TRITOP is also used to raise the projects to an even more professional level and meet the requirements of the restorers. The photos recorded by the system provide the restorers with information about the surface color of the historical objects. In many projects, these photos are mapped via the 3D scan in order to obtain colored and textured meshes. The combination of both solutions provides an informative digital representation of the parts and their individual components.

I hope that this project can serve as an inspiration for museums and cultural heritage institutions dealing with archaeological, as well as ethnographic artefacts.

Bjarte Aarseth - Chief engineer 3D scanning