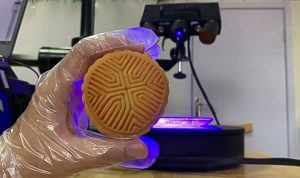

Inspecting electronic connector housings using CT technology

Identifying internal defects and correct connector pin positions of electronic connector housings is crucial for proper functioning of the final product. The advanced CT technology of ZEISS METROTOM 1 is the perfect fit to get deep insights of your electronic parts, allowing for quick and intuitive evaluation and improvement of production processes.