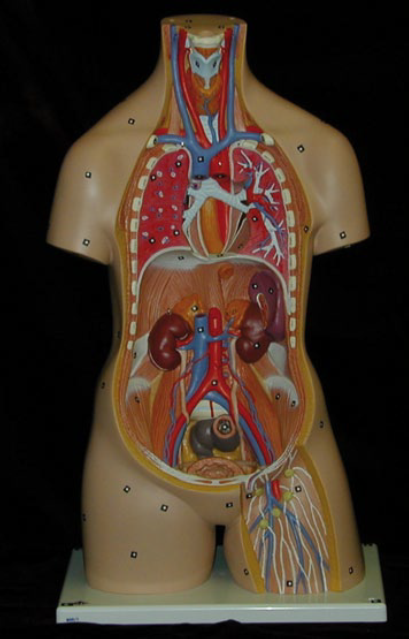

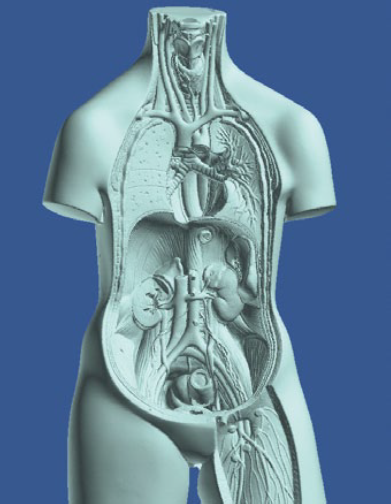

The following application therefore shows the complete digitizing of a torso model and its removable organs. All data is collected in one coordinate system, using the ATOS Q.

First some reference points are applied onto the torso. Then, using the photogrammetry camera and the software, the coordinates of the points are measured with high accuracy. In the next step the organs are placed in position and three reference markers are applied to each added part.

Now a second series of images is taken and from these images the visible reference point coordinates are measured. Using the points on the torso, which are defined in both measurements, the second set of points is transformed into the coordinate system defined by the first measurement.

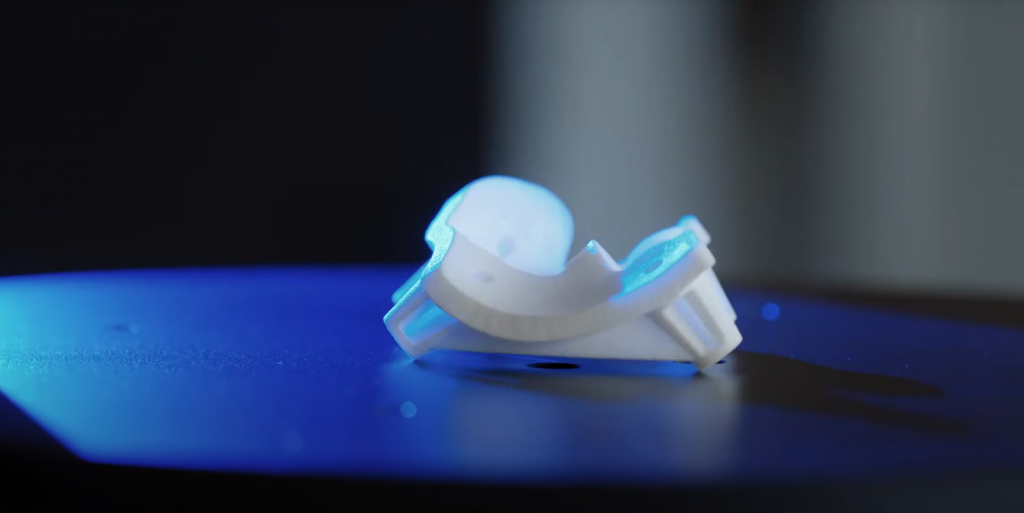

Then the organs are removed and each part is digitized individually using the ATOS Q. If the parts are small compared to the selected measuring area of the ATOS digitizing system, no additional reference points on the part are needed. The part is mounted on a black breadboard. On the board, around the part, additional reference points are placed.

Then the assembly is digitized from different views, using the reference points on the breadboard to merge the different views into one coordinate system. The three predefined reference points are used to merge the data into the global coordinate system. If needed, the part is rotated to allow full coverage of the part.

The torso itself is digitized with the ATOS Q mounted on a tripod and moved in steps around the part, in order to cover all needed areas. The transformation of the individual point clouds is made automatically using the applied reference points. This method is used to digitize big objects, step by step, with high accuracy. The progress of the scanning is visualized on the screen and therefore the complete scanning is simple and straight forward.

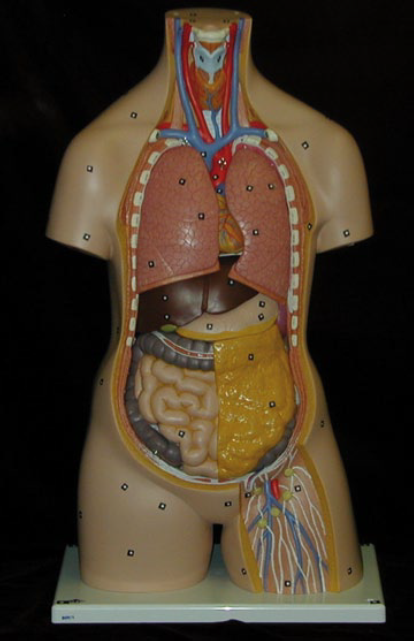

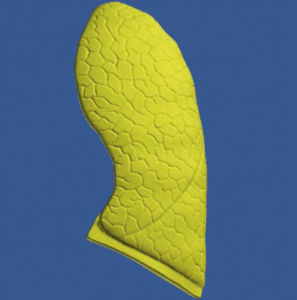

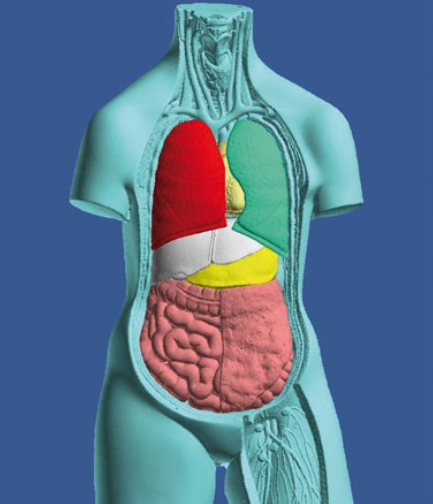

Using the GOM Inspect software, the measured data can be preprocessed and outputted in different formats to meet the requirements of the application. High density clouds, sections as well as thinned out STL data can be generated. Usually, STL data is used to have a RP model made or to mill on the data.

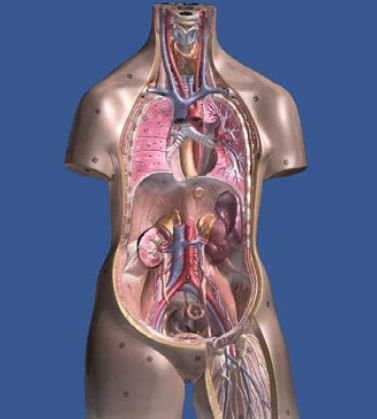

As we use b/w CCD cameras for the digitizing, the color in (5) is artificial and used to visually distinguish each individual part. To be able to visualize the real color in the digitized object, the object is put into a room with good lighting conditions and a digital color camera is used for the photogrammetry measurement. Then the ATOS measurement is made as usual and finally the color information gathered during the photogrammetry measurement is projected onto the digitized data. Using this method, the color quality as well

as the digitized data correspond to the real part.

The color information clearly illustrates details of the lung of this model. Thanks to the technology used, high quality “color polygon meshes” are created as both, shape and color are recorded under optimum conditions.