The weld check process at Huck Cycles

When it comes to quality control of motorcycles, the welded frames takes up a fundamental part in the function, stability and safety of the vehicle. In order to make sure, that all these criteria are being met, comprehensive analysis of the welds is necessary. If this does not happen, consequences such as defects in the entire structure of the welded frame or even damage to other installed components are consequently. To circumvent these obstacles, which can be time-consuming and costly, Huck Cycles in the USA relies on the combination of the ZEISS T-SCAN hawk 2 3D laser scanner and the Weld Check package in the inspektion software of ZEISS Quality Suite.

1.Step: Scanning

Wanting to inspect welds, requires the collection of precise data of the whole frame. The hand-held solution ZEISS T-SCAN hawk 2 is optimal for scanning the frame structure on the spot. Due to its flexible design every inch can be inspected – following the movement of your hand. Moreover, the high quality laser source collects data of the surface in the most precise way possible. The result: a comprehensive 3D model of all the necessary details for checking welds.

2.Step: Evaluation

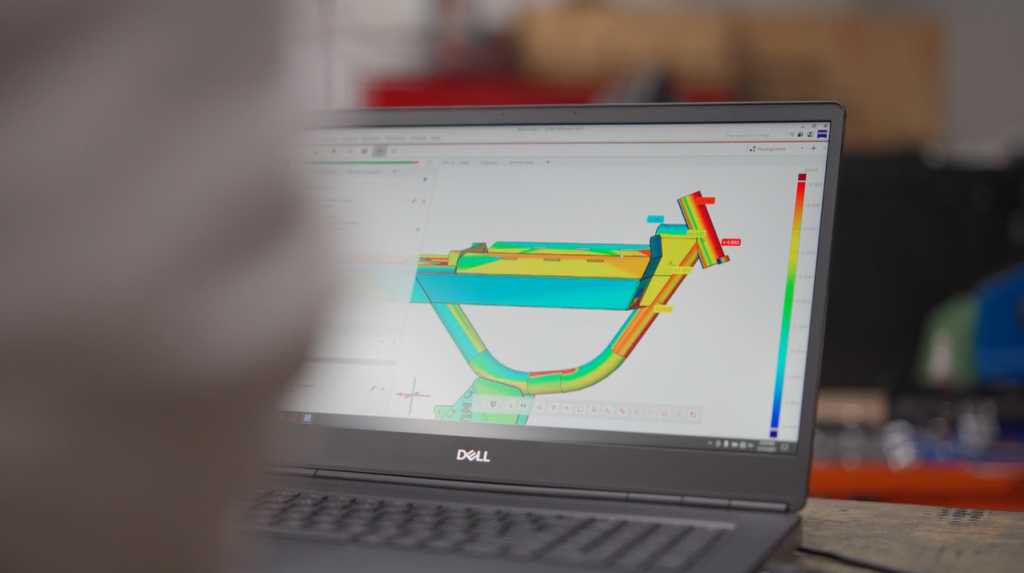

The digitized welded frame can be inspected for weld defects via the Weld Check package of the inspection software. Several evaluation possibilities, like color defect maps, show deviations in an easy way. Based on that information, Huck Cycles can make adjustments to the frame before continuing assembly or producing further faulty parts.

The Weld Check package in our inspection software

The Weld Check package enables automated visual inspection of welds. With one mouse click, welds can be inspected in a 3D scan according to all features of DIN EN ISO 5817. The package also enables the weld inspector to create a reporting of all characteristics. This allows the visual inspection to be digitized and tracked.

Overall you can expect several benefits when working with the software solution, like:

Less manual effort

No more manual measuring required. The weld seam to be inspected is scanned with a 3D scanner and evaluated in the pro version of our inspection software using the Weld Check package.

Detailed and easy inspection of welds

With a click of the mouse, all DIN EN ISO 5817 characteristics can not only be inspected, but also classified directly according to the corresponding evaluation groups. With the help of a simple traffic light system, it is possible to see at a glance whether the characteristics are fulfilled.

Reporting

Tracking and digitizing visual inspection made easy: Both overall reports and individual reports can be created.

Watch the latest How-to video to see the system and software in action:

How to weld check on electric motorcycle frames

The basic structure of a motorcycle is the welded frame. Weld inspection is therefore necessary not only to maintain quality of parts, but also for customer safety. With the ZEISS T-SCAN hawk 2 and the weld inspection package of the ZEISS Quality Suite, you can easily scan, classify and inspect welds. Let Juan show you how it’s done.

Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com