3D scan the worlds largest ship propellers with T-SCAN hawk

Are you ready for some quality control of the largest ship propellers worldwide? MMG makes 3D metrology in heavy metal casting tangible.

Are you ready for some quality control of the largest ship propellers worldwide? MMG makes 3D metrology in heavy metal casting tangible.

In the vintage race car community, everyone knows him, even if he doesn’t like to put himself out there. He is the man to see when it comes to making new from old: Mr. Friedrich Burgstaller, managing director of FB Prototypen GmbH. For more than 30 years he has been pursuing his absolute passion: Rebuilding historic racing and sports cars.

Our partner WESTCAM in Austria met him for an interview and asked him about his work and the “project powered by WESTCAM”.

3D metrology is already being used in medical technology. Be it for the production of precisely fitting prostheses or also models to illustrate physical conditions. The goal is the generation of data which can then be used for educational purposes, e.g. in form of augmented reality.

Always be up to date on all things 3D scanning. Receive news on #HandsOnMetrology and our #HOMunity by just subscribing to our free newsletter.

Sustainability is an important factor in manufacturing and highly requested by customers of Precupa. How the company can meet the demands by using 3D metrology, you get to know here.

Long time no see! After 3 years we finally got to talk about 3D metrology live again. Here are the highlights of the trade show ‘Control’.

Get into the nitty gritty of 3D scanning. The annual issue of the magazine highlights the recent innovations in the area of industrial quality solutions.

Geek Talk is all about the passion and fun that goes far beyond our daily tasks and jobs. In this video format our 3D scanning

More than 60 partners worldwide support our customers in setting new standards in 3D metrology everyday – and the global community is constantly growing. For our Scan Around The World challenge, they took us to local sights and helped us to explore country-specific items with our 3D scanning technologies.

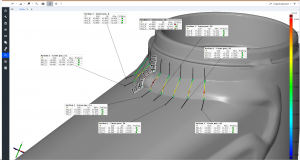

The new Weld Check app in ZEISS INSPECT ensures automated and standardized inspections of welds. Together with the T-SCAN, selected scan data can be evaluated with maximum comfort.