Eine 3D-Scanning-Lösung für komplexe Messungen und Prüfaufgaben

Zuverlässig, vielseitig, kompakt

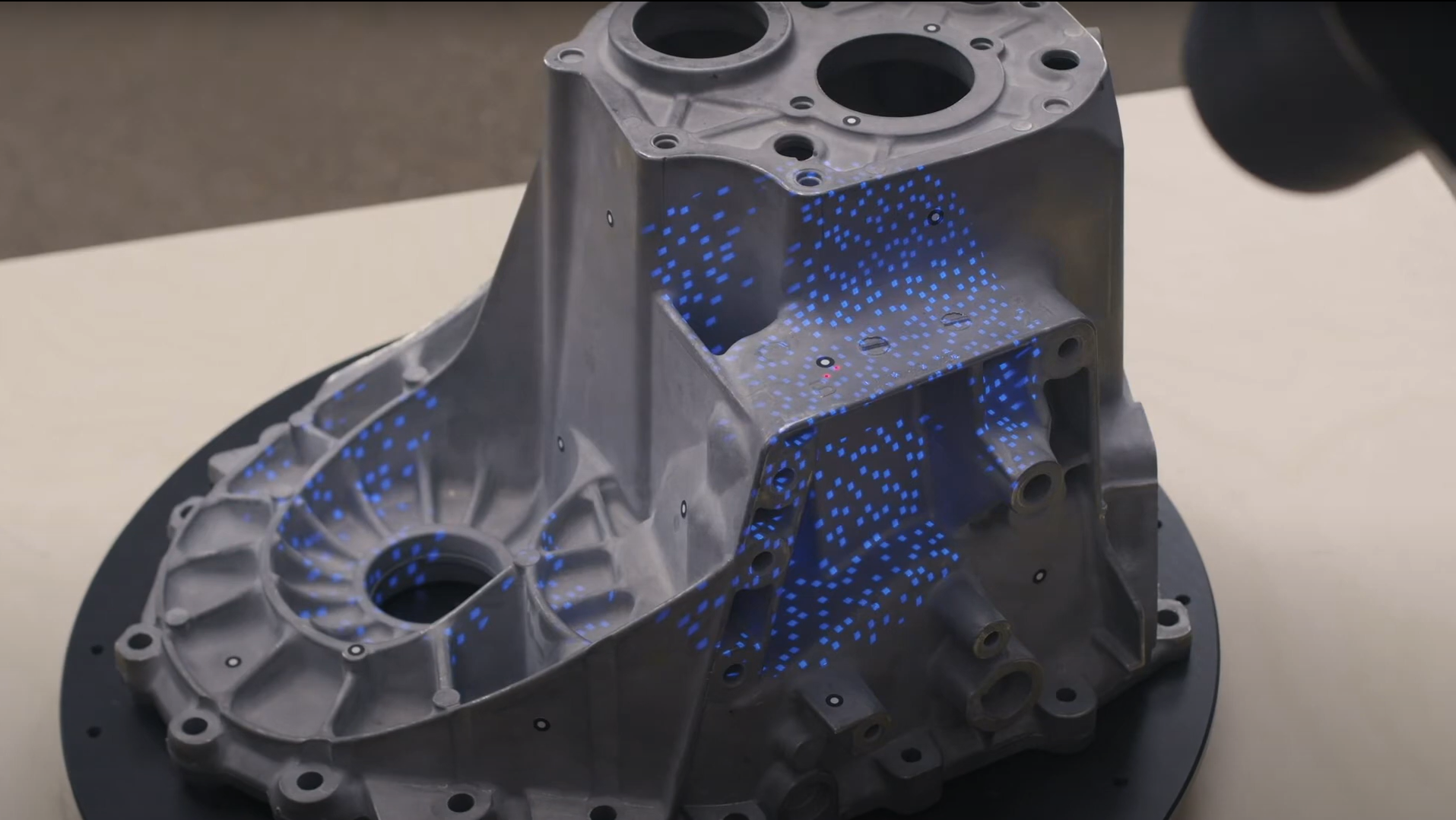

Mobil, vielseitig und präzise: ATOS Q ist bereit für den Einsatz in der Produktionsumgebung. Konzipiert als flexibler 3D-Scanner für komplexe Mess- und Inspektionsaufgaben, erfüllt er hohe messtechnische Anforderungen für viele Branchen. In Kombination mit ZEISS INSPECT ist er ein schnelles, kompaktes und einfach zu bedienendes optisches 3D-Messsystem mit echter ATOS DNA.

Speziell für die Industrie entwickelt

Ausgestattet mit Spitzentechnologie

Schnelle Ergebnisse, außergewöhnliche Leistung

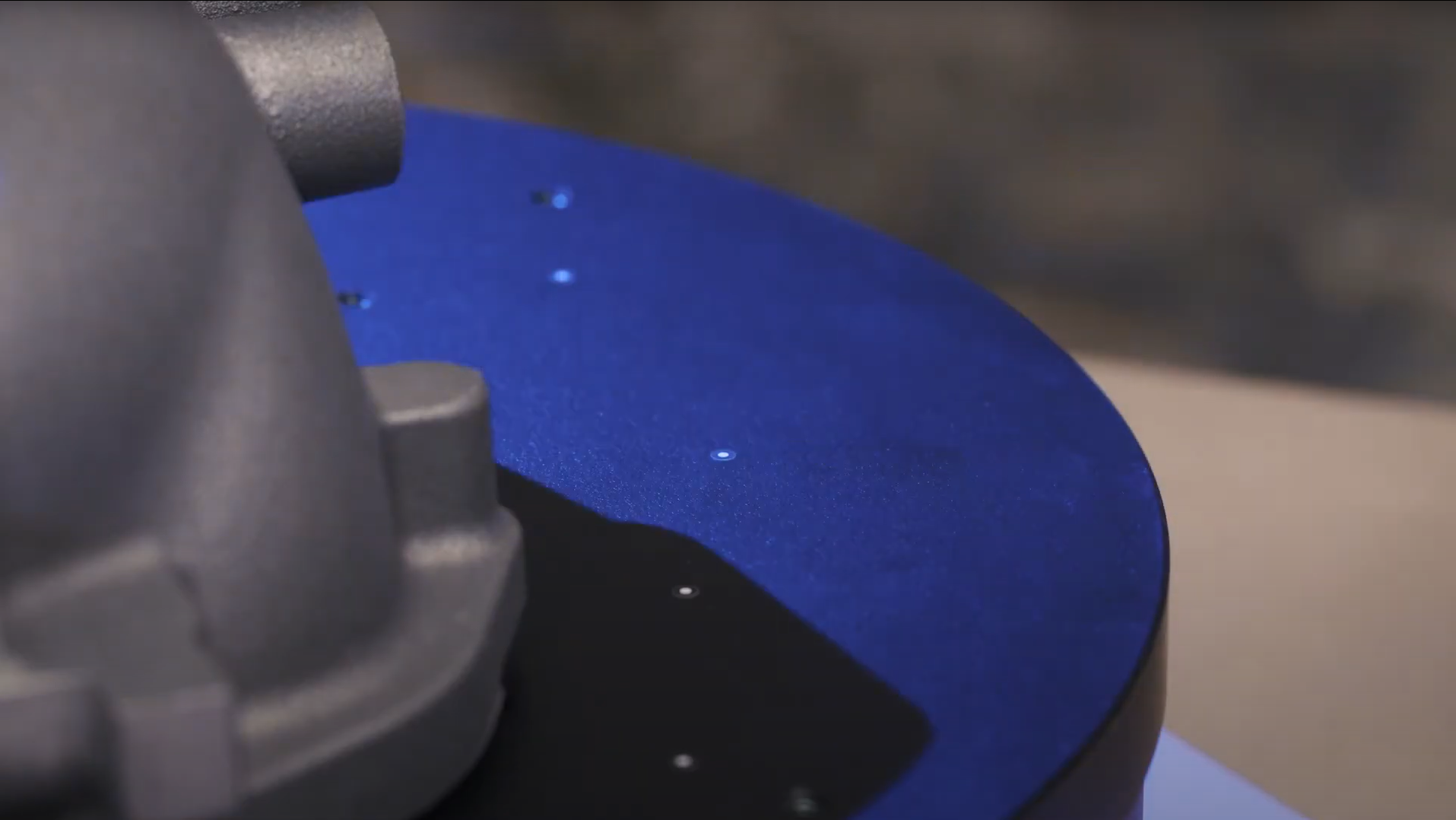

Blue Light Technology: hochpräzise Daten in besonders kurzen Messzeiten

Präzise Streifenmuster werden auf die Objektoberfläche projiziert und von zwei Kameras nach dem Stereokameraprinzip erfasst. Unsere Projektionstechnologie arbeitet mit schmalbandigem blauen Licht: Störendes Umgebungslicht wird bei der Bildaufnahme ausgefiltert.

Extrem vielseitig und bereit für jede Herausforderung

Manuell

Mit nur 4 kg und seiner kompakten Bauweise ist der 3D-Scanner ATOS Q leicht und einfach zu bewegen. Auf einem Dreibeinstativ ist er im Messraum, aber auch mobil in der Produktion einsetzbar.

Halbautomatisiert

In Kombination mit einem Dreibeinstativ, alternativ einem Tischstativ und dem Drehtisch ROT 350 oder einem Motorisierungskit, ist ATOS Q auch halbautomatisiert verwendbar.

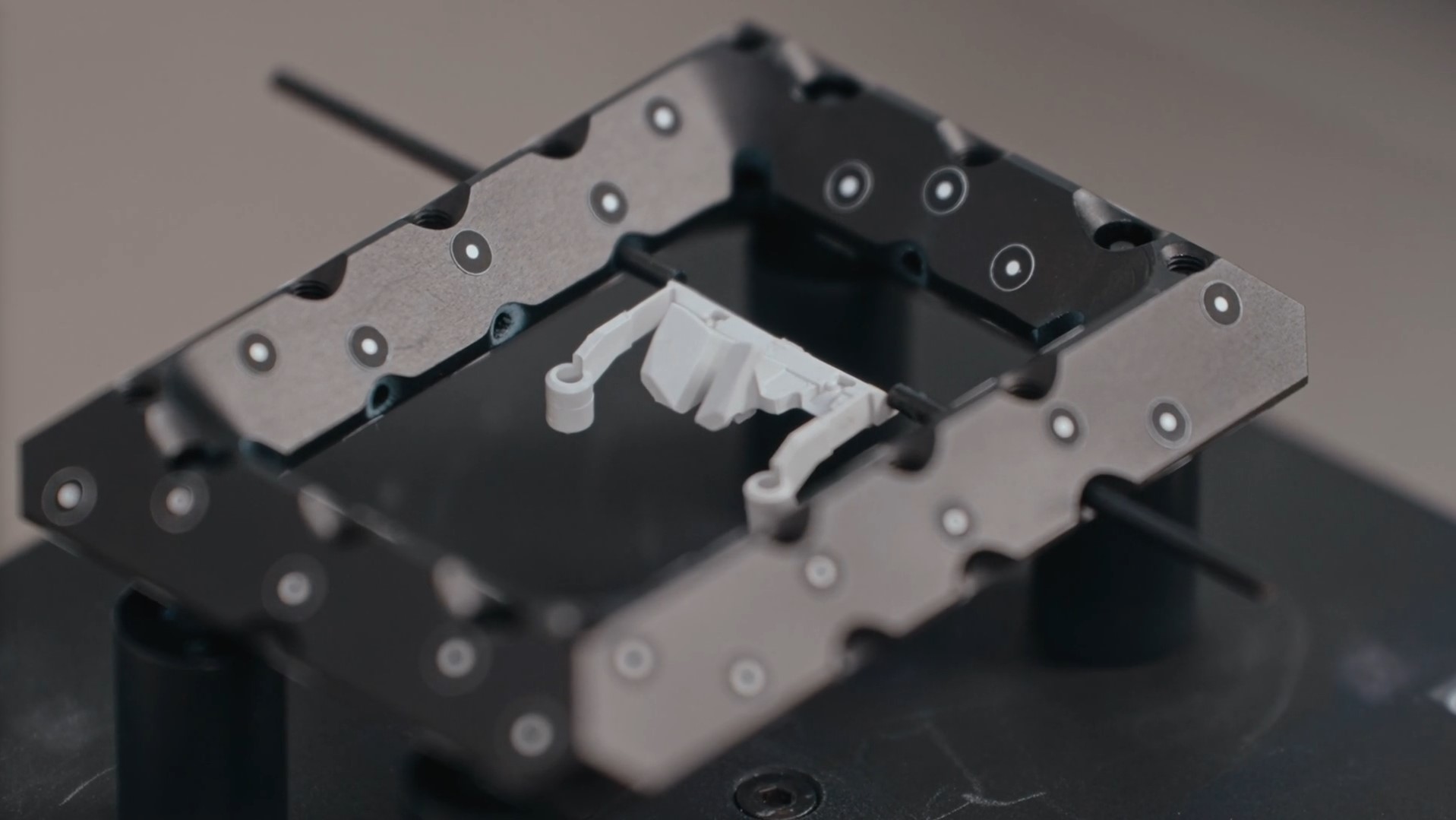

Qualität gestalten mit mehreren Messvolumen

Die Wechselobjektive des ATOS Q gewährleisten hochpräzise Messungen von kleinen bis mittelgroßen Bauteilen. Ein Wechsel vom kleinsten zum größten Messvolumen ist dank der festen Kameraposition sehr einfach möglich.

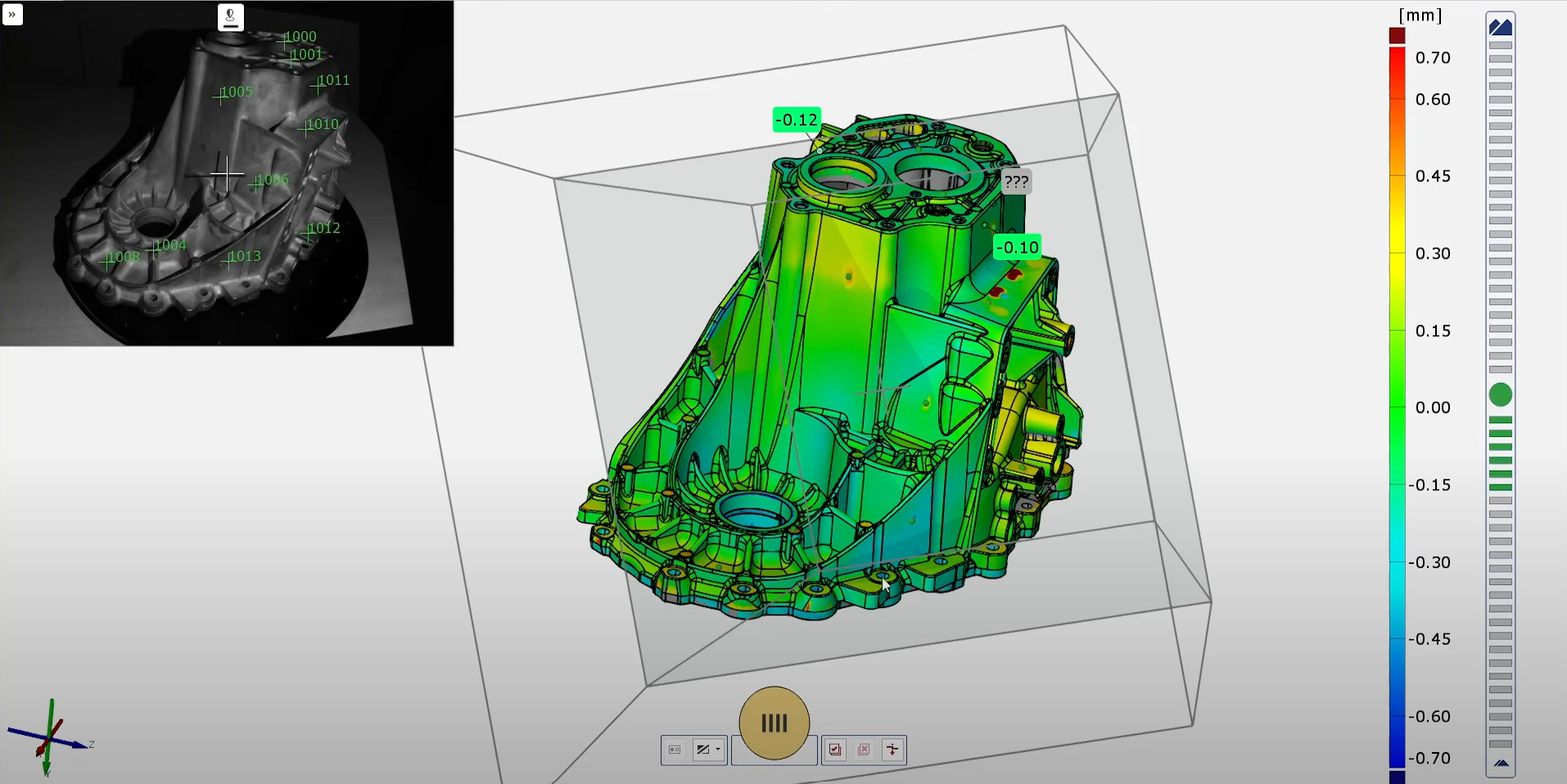

ATOS Q sichert die Qualität

- von additiv gefertigten Bauteilen

- für Kunststoff- und Spritzgussteile

- in den Verfahren Sandguss, Druckguss und Feinguss

- von Metallumformprozessketten (stanzen, biegen, ziehen und pressen)

Technische Daten

Entdecke ZEISS INSPECT - Pro Line für ATOS Q

Möchtest du noch mehr wissen?

Nimm Kontakt mit deinem lokalen #HandsOnMetrology-Partner auf.

Mehr erfahren

i

Please select the topic you seek more information aboutHow to save time with ZEISS INSPECT

Let Matt show how quality control becomes more efficient using the full version of ZEISS INSPECT. Whether inspecting one or multiple parts, templates transfer pre-made inspection steps in one click. Trend project function furthermore helps when all parts need to be checked at once – making evaluation fast, easy and intuitive.

All functions shown are available in the current software version.

Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

How to scan small parts using compact 3D scanners

3D scanning of small parts and fine details is often a challenge that can take a lot of time. In this How-to, Matthias shows you how you can take the 3D scanning process to a new level with the help of ATOS Q, GOM Scan 1 and the Motorization Kit.

Do you have any question on our 3D scanners? Contact us via support@HandsOnMetrology.com

How to 3D scan multiple parts with ATOS Q

Learn how to scan multiple identical parts simultaneously using the ATOS Q and a rotation table. Simply choose the workflow assistant for scanning multiple parts and follow the software as it guides you through the scanning process. Since the rotation table is marked with reference points, you can start scanning straight away. Partitioning the parts and aligning top and bottom scans is done with just a few clicks.

Do you have any question on our 3D scanners? Contact us via support@HandsOnMetrology.com

How to eliminate plastic warpage in Quality Control

Annoyed about plastic warpage and how it makes quality control of unassembled parts difficult? In this video, Toon shows you how to solve this problem: with the De-warp function that can be found in the full version of ZEISS INSPECT . It puts scanned plastic parts into a virtually assembled state, allowing you to check their dimensions as if they were assembled.

All functions shown are available in the current software version.

Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

So funktioniert der digitale Zusammenbau in ZEISS INSPECT

Wie man Objekte ohne Referenzpunkte scannt

Schnellere 3D-Scans mit einem automatischen Drehtisch

How to get even more out of your ATOS Q

Let Dokus show your the benefits of upgrading your ATOS Q with ZEISS INSPECT – Pro Line: The software offers a wide range of extra features for analysis and inspection and improved functionality. Three of the powerful add-ons are:

1) the use of a touch probe with your system to combine scanning and probing.

2) the use of your system as a live tracking device.

3) the use of your system as a projector – to project elements directly onto the part.

ATOS Q: Zu einem kleinen Messvolumen wechseln

ATOS Q: How to measure big parts

Use the 3D scanner ATOS Q to scan a large part with the measuring volume MV500. Even if the object is bigger than the measuring volume, you can capture it easily using reference points and stitching scans to get a high quality result including small details.

Chapter:

00:42 Start new project and perform first scan

01:24 Stitching scans with reference points

02:01 Finish scan

ATOS Q: How to measure top and bottom of a part

In this video, Dokus measures a part from the top and the bottom side to create a digital twin. A fast and easy workflow with the 3D scanner ATOS Q, assisted by the automatic rotation table and GOM Inspect. After measuring, simply combine and polygonize the data.

Chapters

00:38 Start new project

00:54 Use rotation table

01:38 Flip over the part

01:55 New measurement series

02:42 Combine top and bottom

03:23 Polygonize and recalculate

ATOS Q: Measure with the automatic rotation table

Learn how to use the automatic rotation table to speed up the 3D scanning workflow with ATOS Q. GOM Inspect allows you to choose the number of automatic rotations. A rule of thumb: With 8 rotations you capture almost every aspect of the part.

Chapters

00:45 Rotate rotation table

01:14 Select scanning template and perform first scan

01:41 Use rotation table

02:20 Polygonize and recalculate

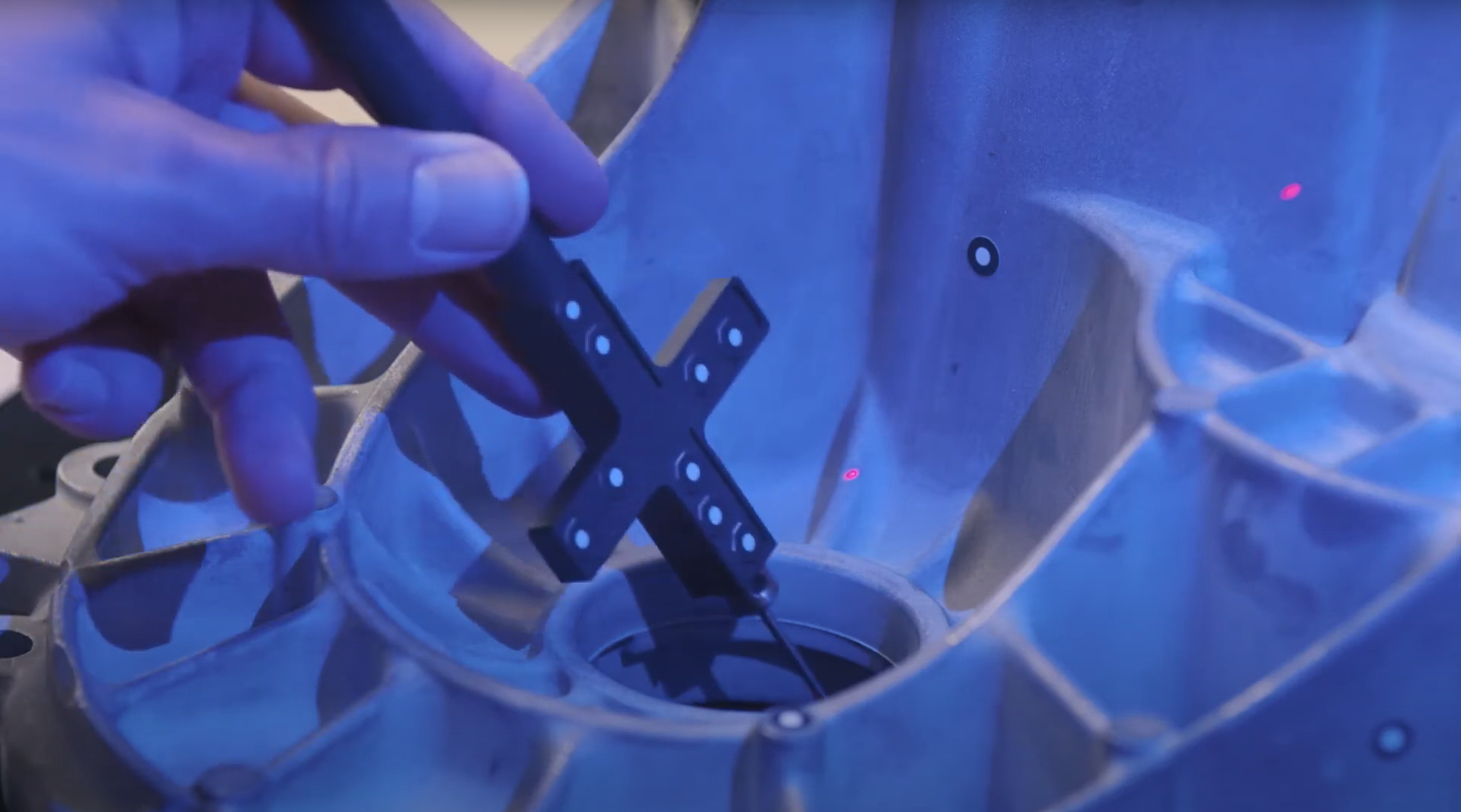

ATOS Q: Add single points with a touch probe

Learn how to use a touch probe to capture 3D data. Dokus shows you how to scan in difficult-to-reach areas and explains guided touch probe measurements in GOM Inspect Suite.

Chapters

00:27 The touch probe

00:49 Live workspace

01:16 Select touch probe

01:44 Finish measurement

02:00 Guided touch probe measurements

02:42 Start guided touch probe measurements

ATOS Q: Tips & tricks to scan even faster

Dokus gives valuable tips on using the 3D scanner ATOS Q. Learn how to measure the automatic exposure time and move the focus point, how to change into fast scan mode – if you don’t need details – or how to manually cut out points.

Chapters

00:42 Automatic exposure time

00:59 Move the focus point

01:36 Fast scanning

02:22 Cut out points

02:52 Selection tools

ATOS Q: Start a project in ZEISS INSPECT

Let Dokus show you how to make your first scan with ZEISS INSPECT. He takes you from the start screen to the checkered flag: a very detailed mesh. See different workspaces and scanning templates. Learn how to scan and watch what happens when you rotate the table.

All functions shown are available in the current software version.

Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

Chapters

00:42 Start software

01:03 Workspaces

01:33 Digitizing workspace

01:58 Main toolbar

02:22 First scan and cut out background

02:50 Reference points

03:18 Polygonize and recalculate

ATOS Q: Fast inspection with GOM Inspect

ATOS Q: Unboxing your new 3D scanner

Meet Dokus and the ATOS Q with its two cases. The first case contains the ATOS Q sensor and everything you might need on location, from rotation table to measuring volumes or the calibration plate. The second, smaller case contains the laptop and the mobile controller.

Chapters

00:27 The case

00:50 First compartment level

01:05 Second compartment level

01:26 Bottom compartment level

01:34 Mobile controller

01:52 The laptop