Vom 3D-Scan zum CAD-Modell mit ZEISS REVERSE ENGINEERING

Du suchst eine einfache Lösung für Flächenrückführung? ZEISS REVERSE ENGINEERING liefert dir dafür alles, was du brauchst. Scanne deine Bauteile in ZEISS INSPECT oder einer anderen Software und importiere die STL- oder PLY-Daten und ASCII-Formate in ZEISS REVERSE ENGINEERING. In wenigen, gut geführten Schritten entsteht ein hochgenaues CAD-Modell, das du in gängige Formate wie IGES, STEP oder SAT exportieren kannst. Eine Software, mit der du deine Aufgaben einfach und schneller erledigen kannst.

Eine leistungsstarke Software für Flächenrückführung

Geführter Workflow

ZEISS REVERSE ENGINEERING macht es einfach, ein CAD-Modell aus Scandaten zu generieren, etwa aus einem Polygonnetz oder einer Punktwolke. Die Software führt dich Schritt für Schritt durch den Prozess.

Hohe Genauigkeit

ZEISS REVERSE ENGINEERING liefert dir CAD-Oberflächen mit höchster Genauigkeit. Das ist besonders wichtig, wenn du Plastikteile produzieren möchtest, die hohe Anforderungen an Präzision stellen.

Effektive Funktionen

Bereite deine Daten vor, in dem du Löcher füllst oder Flächen glättest, bearbeite sie weiter mit Features wie “Dynamic best fit” oder “Extrusion”.

Generiere dein CAD für jede Form

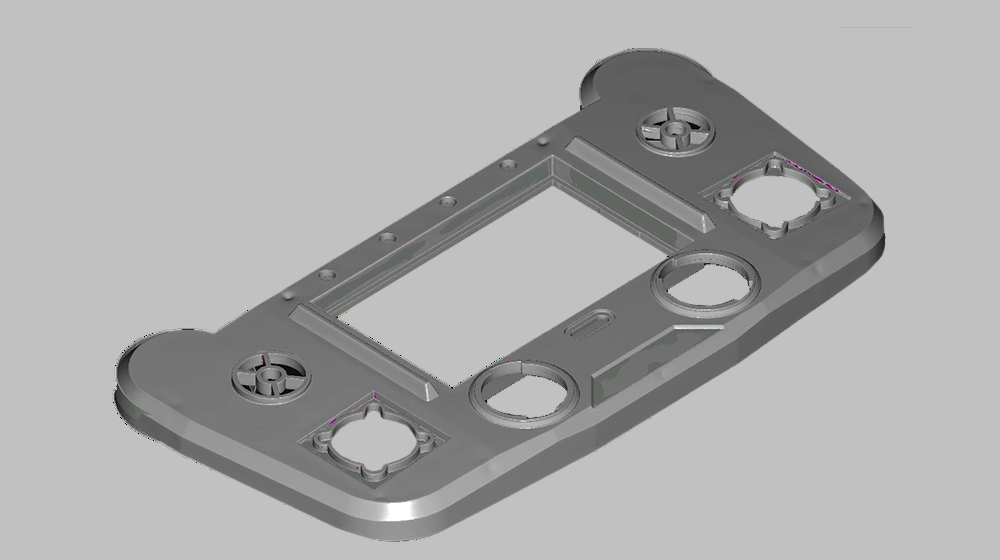

Scan to CAD for geometrical part

Follow Josh’s instructions to scanning a geometrical part and transforming it into a CAD model using ZEISS REVERSE ENGINEERING and the GOM Scan 1. First, he scans a symmetrical part and cuts it in half. Then, he creates basic elements of the part with planes from the mesh. Next, he creates a body from these elements and add details. Finally, he mirrors the part – and has a perfect CAD model of the part.

Geometrische Bauteile

Flächenrückführung für geometrische Formen? Exportiere deine Daten einfach in ZEISS REVERSE ENGINEERING und fange an zu gestalten, zu kombinieren, zu extrahieren und anzupassen. Die Software führt dich durch den gesamten Prozess und du erzeugst genau das Ergebnis, das du benötigst.

Freiformflächen

Nutze verschiedenste Funktionalitäten, um höchste Genauigkeit für Freiformflächen zu erreichen. Um deine Daten umzuwandeln, verwende zum Beispiel “Oberflächenannäherung an Punkte”. Anschließend führt dich die Software Schritt für Schritt durch den Prozess bis zur Erstellung deiner Form.

Scan to CAD for freeform part

Discover how Josh uses the software ZEISS REVERSE ENGINEERING to create a mold for a freeform shaped part. First, he creates a freeform surface of an already scanned part. Then, he creates a solid cube around the part. Finally, he subtracts the freeform surface from the cube to create the final mold.

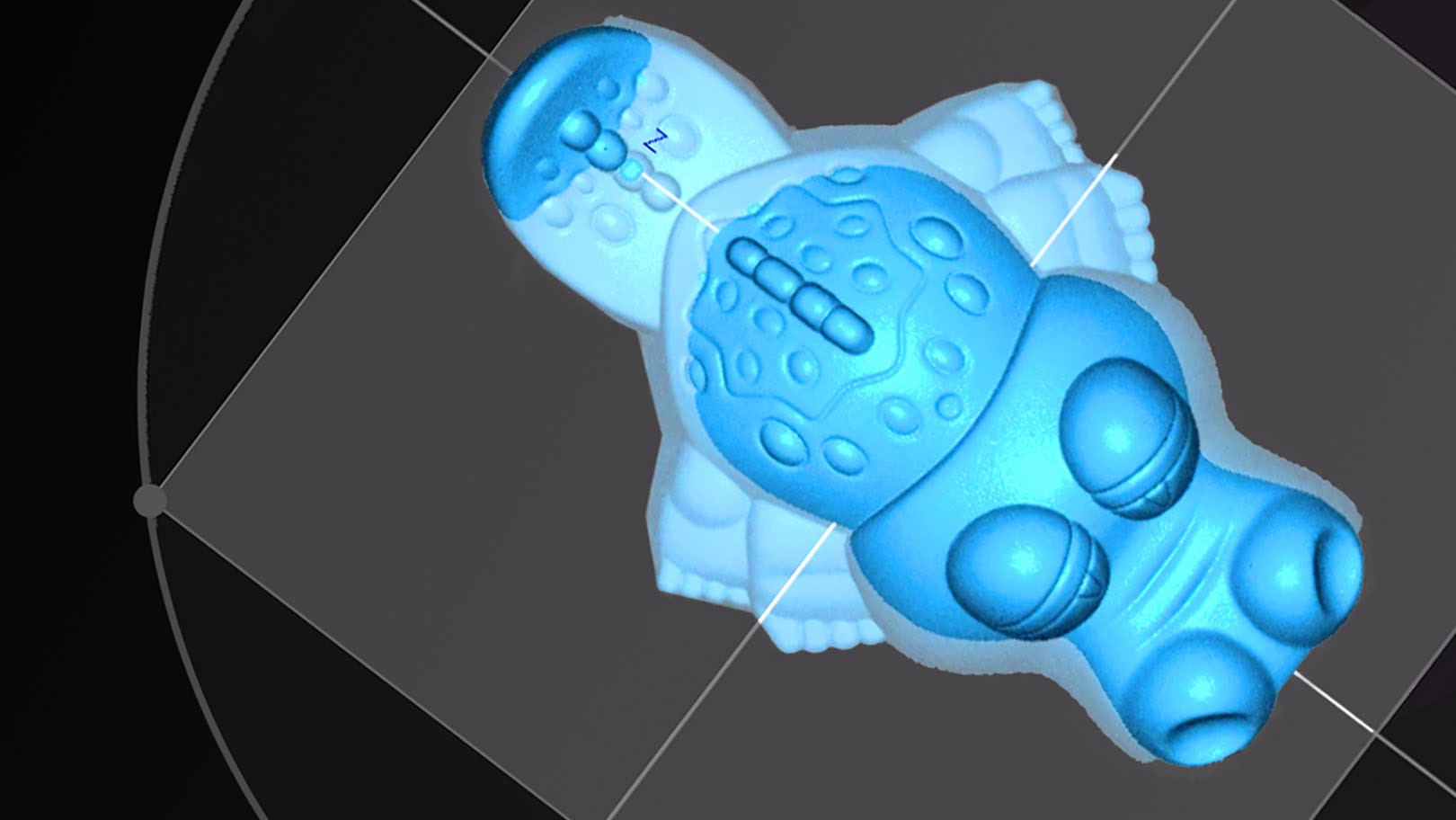

Scan to CAD for organic shaped part

Watch Josh as he turns the scan of a highly detailed, organic shaped miniature figurine into a CAD model using the software ZEISS REVERSE ENGINEERING. First, he cleans up the mesh, closes holes and removes unwanted features. Then he simply exports the mesh to ZEISS REVERSE ENGINEERING. The result: a perfect CAD model, that follows the natural shape of the part.

Organische Formen

Ob du ein CAD-Modell mit organischer Form erzeugen, weitere Schritte zur Flächenrückführung machen oder gestalten möchtest – du brauchst nur ein paar wenige Arbeitsschritte dafür. Im Video erfährst du mehr.

Ganz einfach ein hochpräzises CAD-Modell generieren

Wie du deinen 3D-Scan in ein CAD-Modell verwandelst

Hast du noch Fragen zu ZEISS REVERSE ENGINEERING?

Du kannst uns jederzeit kontaktieren. Wir helfen dir gerne weiter.

Mehr erfahren

i

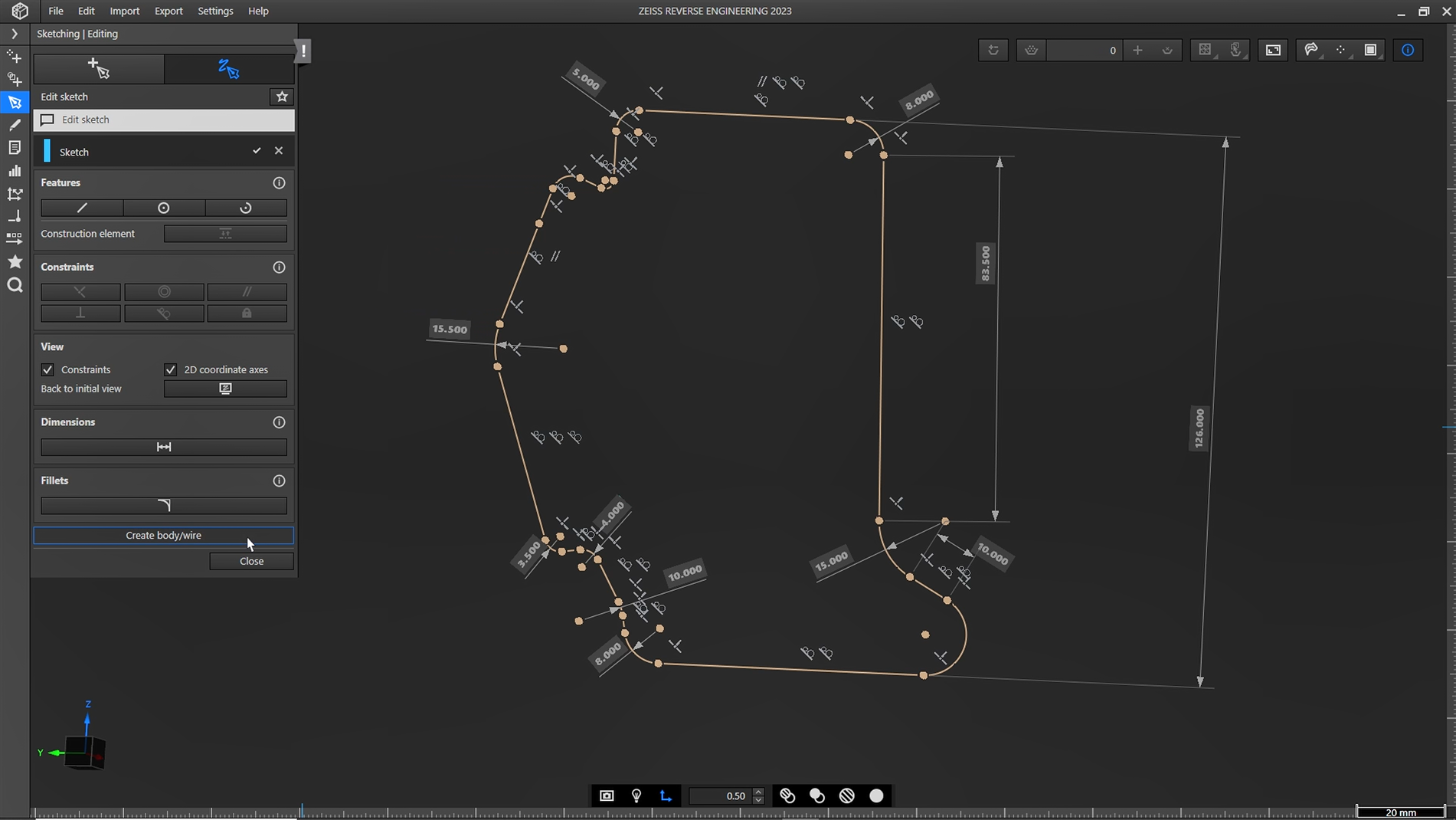

Please select the topic you seek more information aboutNew Sketching function in ZEISS REVERSE ENGINEERING

Looking for an easy way to get more control over your reverse engineered models? With the new sketching function in ZEISS REVERSE ENGINEERING, creating CAD models is easier than ever. Your benefit: fully dimensioned and constrained CAD from scan data.

Do you have any questions about ZEISS REVERSE ENGINEERING? Contact us via support@HandsOnMetrology.com

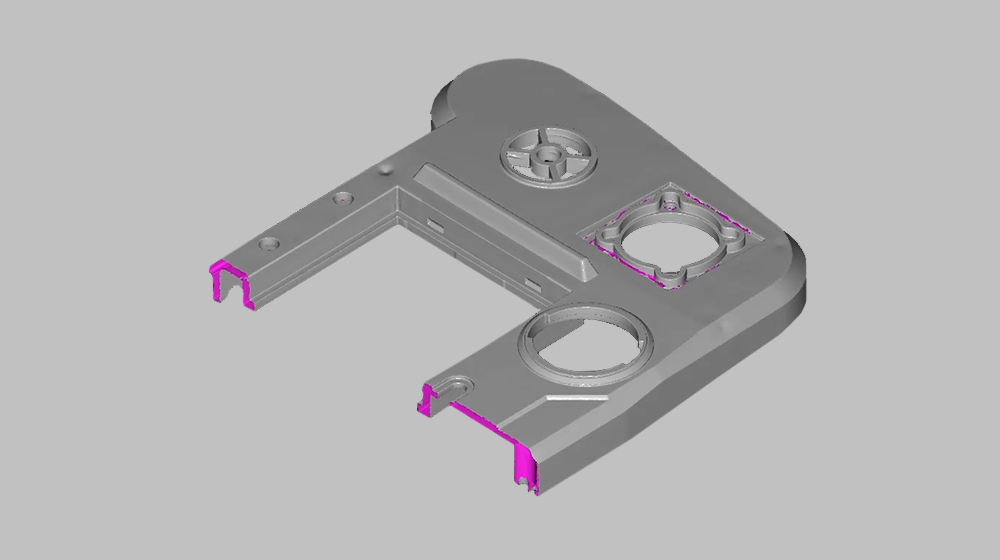

ZEISS REVERSE ENGINEERING: How to create a CAD file out of manually modelled parts

Looking for an easy way to create a CAD out of your individually modelled part? Let Matt show you how! With the help of the ATOS Q and the ZEISS REVERSE ENGINEERING software the part gets digitized and undergoes step by step virtual modeling. Helpful features support the process to enable fast and intuitive work.

All functions shown are available in the current software version.

Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

ZEISS REVERSE ENGINEERING: Importing data

Take it from Josh: Importing data into ZEISS REVERSE ENGINEERING is just as easy as importing it into ZEISS INSPECT. If ou’re already using ZEISS INSPECT, simply export into ZEISS REVERSE ENGINEERING. Alternatively, you can drag and drop files from your file explorer or use the import option as the top of ZEISS REVERSE ENGINEERING. Want to know which file types are supported? Simply take a look at the user guide.

All functions shown are available in the current software version.

Got any questions on the ZEISS software? Contact us via support@HandsOnMetrology.com

ZEISS REVERSE ENGINEERING: Edit and align meshes

Let Josh show you how to align and edit your mesh in ZEISS REVERSE ENGINEERING. Step 1: Align your mesh with the „best fit via three planes“ function to review your part in an intuitive manner. Step 2: Edit your mesh by closing small holes with the „fill holes in mesh automatically“ function. Now you have a fully closed and aligned mesh without any unwanted data – and you’re ready to start the reverse engineering process.

All functions shown are available in the current software version.

Got any questions on the ZEISS software? Contact us via support@HandsOnMetrology.com

ZEISS REVERSE ENGINEERING: Tips and tricks

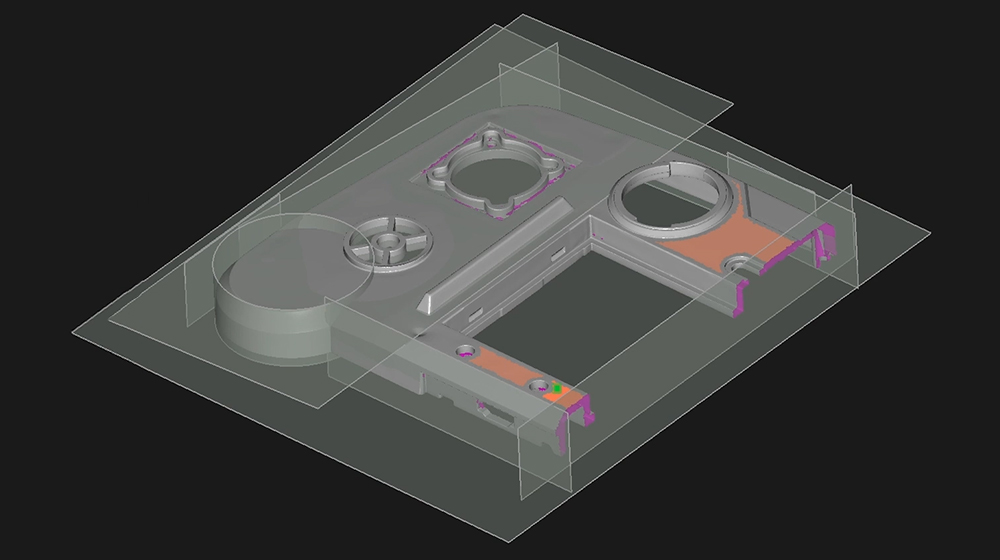

In this video, Josh lets you in on some handy tips and tricks to help you get started even faster with ZEISS REVERSE ENGINEERING. Learn how to bookmark your favorite functions. Discover how the transparency tool can help you get a better look at specific elements. Learn about how the snapshot tool makes it easy for you to create images for reports. Start using the „fit to screen“ icon to get a better view of your part. And minimize clicks by looking at the shortcut list in the user guide.

All functions shown are available in the current software version.

Got any questions on the ZEISS software? Contact us via support@HandsOnMetrology.com

ZEISS REVERSE ENGINEERING: Software user interface

In this video, Josh provides a quick overview of the ZEISS REVERSE ENGINEERING software user interface and shows you how to set up and start using the software. He covers the basics, including the software settings, the workspaces and some additional functionalities. Watch it and get started!

All functions shown are available in the current software version.

Got any questions on the ZEISS software? Contact us via support@HandsOnMetrology.com

ZEISS REVERSE ENGINEERING: Most common functions

Discover the most common functions of ZEISS REVERSE ENGINEERING. In first place: the „extract surfaces from parts“ function, which leads directly to the „extract solid body“ function – two powerful tools, especially for geometry-based parts. Second place: the creation of symmetric parts. Third place: the creation of freeform surfaces. And last but not least: the analysis function of your parts. Let Josh show you what’s what.

All functions shown are available in the current software version.

Got any questions on the ZEISS software? Contact us via support@HandsOnMetrology.com

ZEISS REVERSE ENGINEERING: How to transform your 3D scans into CAD models

Meet Josh and let him show you how to transform your 3D scans into CAD models using the software ZEISS REVERSE ENGINEERING. Wether you want to reverse engineer a geometrical part, a freeform shaped part or an organic shaped part – Josh gives you a quick introduction to each task, from scanning to obtaining a CAD model.

All functions shown are available in the current software version.

Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

Entdecke unsere neuesten Videos

Videos

Lösungen

Digitale Events

Follow us

Trag dich in unseren Newsletter ein

- Datenschutzerklärung

- Impressum

- ©2025. All Rights Reserved

Follow us

Videos

Lösungen

Digitale Events

Trag dich in unseren Newsletter ein

- Datenschutzerklärung

- Impressum

- ©2023. Alle Rechte Vorbehalten.