Ensuring quality of mid-sized parts

The romanian site of a plastics processing company is dedicated to the production of plastic components for the automotive industry. Previously, the quality control processes were very slow. However, with the help of our partner InMAACRO and 3D scanning solutions, a wide variety of parts can now be inspected reliably and quickly for possible defects.

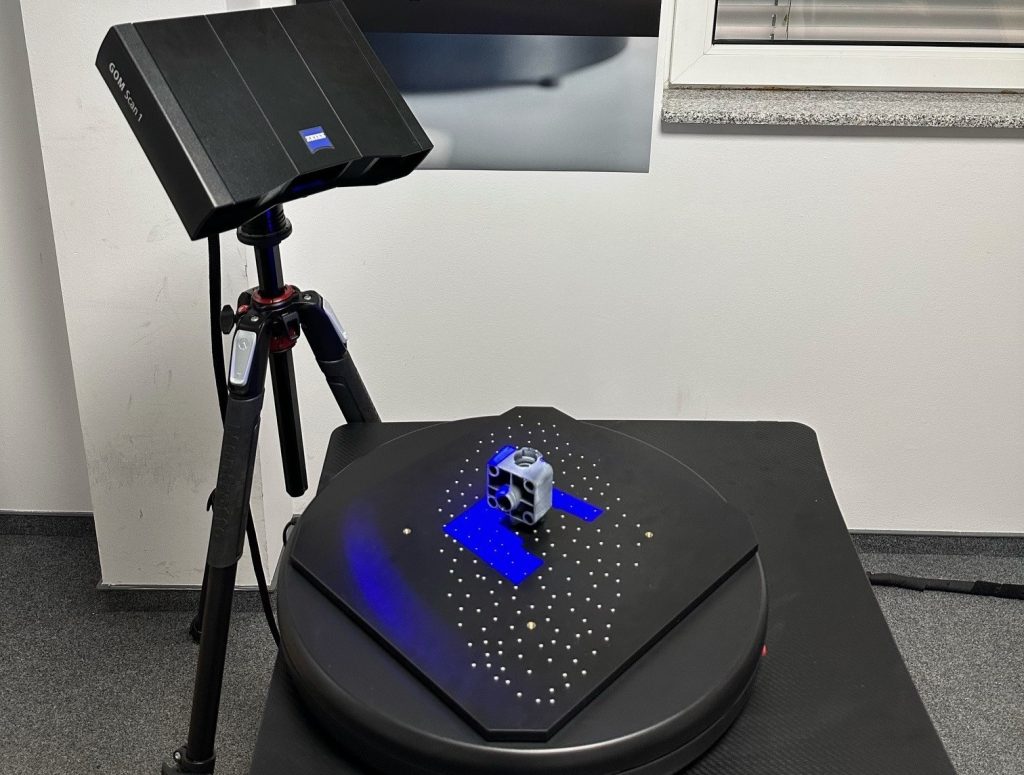

The focus here is on parts up to 2 meters in size. The components to be inspected are usually black, but the color may also vary. In order to meet the requirements of the automotive industry and to remain competitive, the company wanted to implement an even more precise and user-friendly system for quality control. With the GOM Scan 1, they found the right solution for the quality assurance process in their quality room. It delivers a high amount of data for each plastic part. Furthermore, the fringe projection system is easy to use and can be applied without expert knowledge on 3D metrology. The measuring volume of 200 was the way to go to inspect larger parts as well as more detailed geometries.

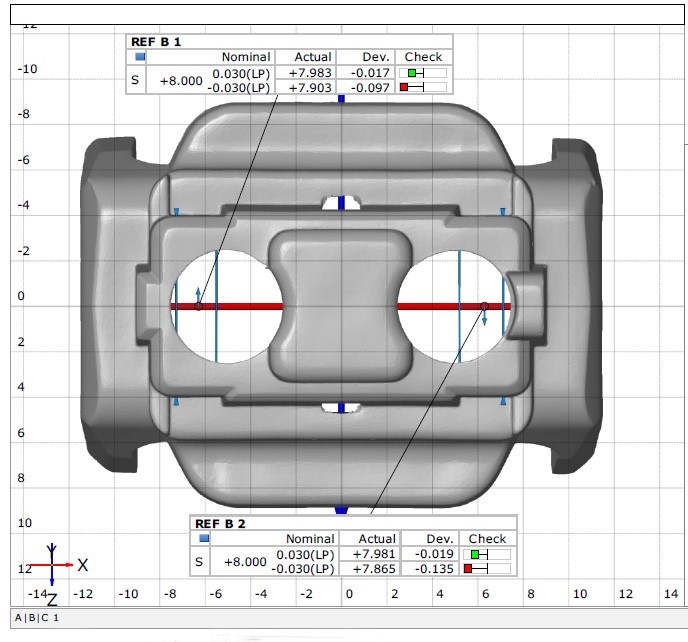

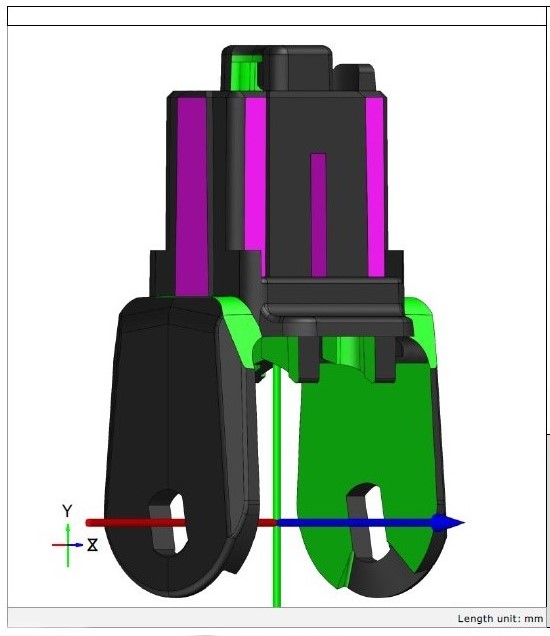

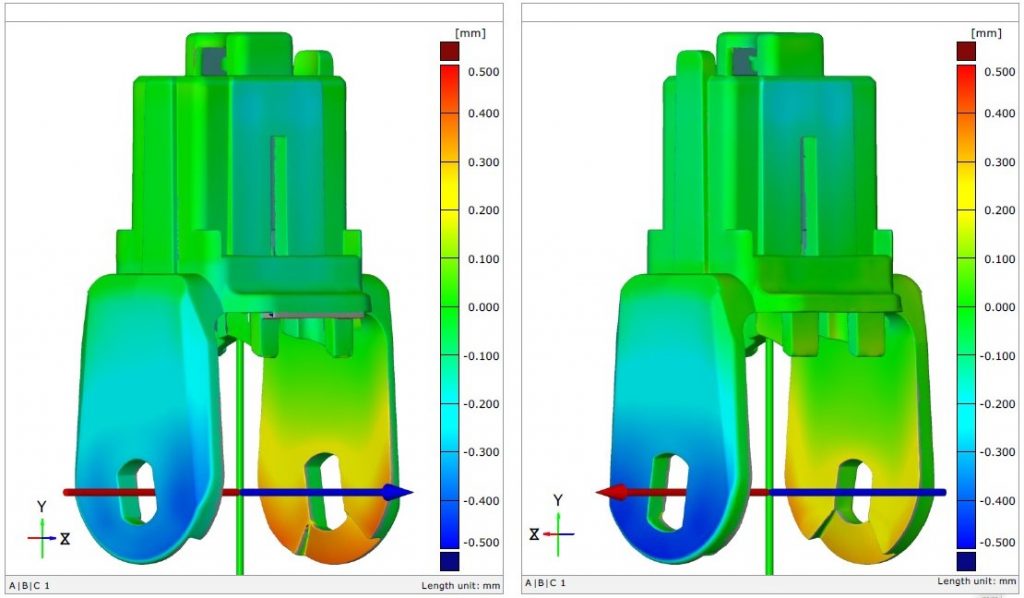

Precise data evaluation

The ZEISS INSPECT software proved to be the perfect complement to the 3D scanner. The intuitive operation of the 3D scanner could be extended with the all-in-one software solution. The use of ZEISS INSPECT provided the company with a wide range of evaluation options that could be adapted to the various inspection tasks. This made it possible to deliver fast, highly precise statements about product quality. Rapid intervention in the event of inadequate quality could be quickly identified and rectified.

Learn more about GOM Scan 1

Visit our website to find a local dealer and receive more information.