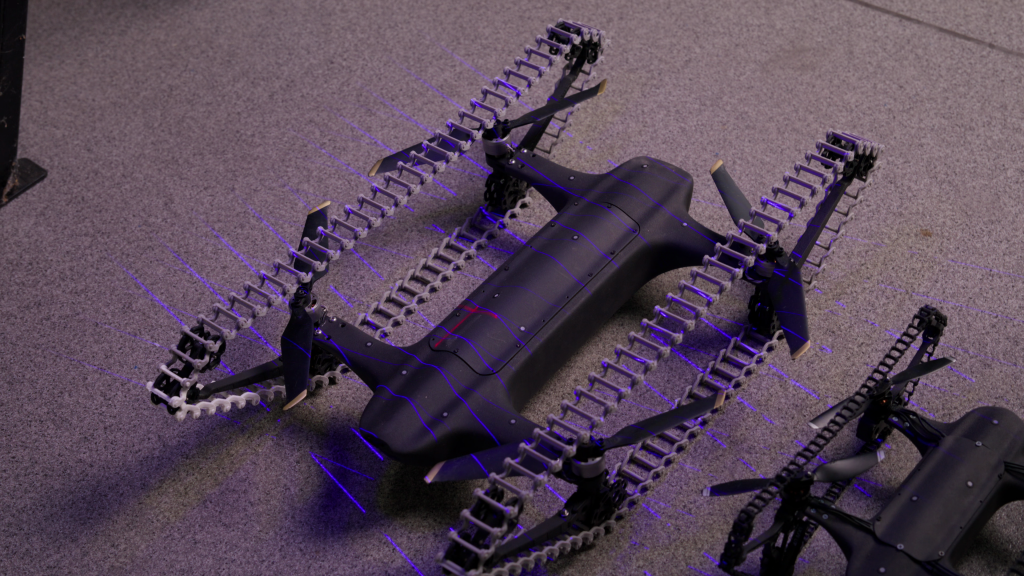

B-TECHNOLOGY began its journey in 2013 with the vision to enhance drone capabilities. What started as a university project evolved into a company with 4 employees. The company is now a hub of innovation, specializing in product design, engineering, CNC milling, 3D printing, and 3D scanning.

Improving drone performance with 3D scanning

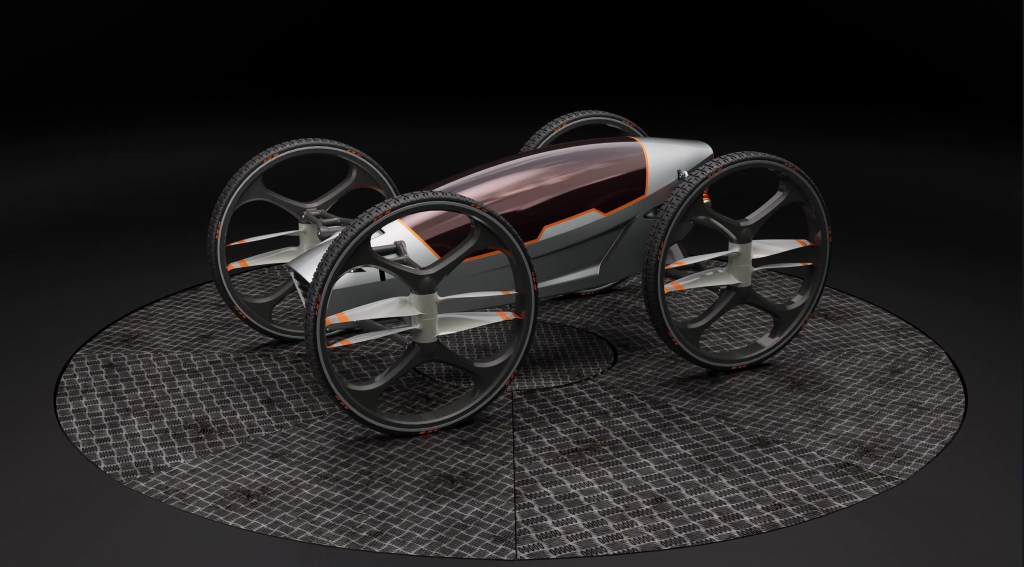

Starting off with the creation of a flying and driving drone, the company has now expanded to the development of the Beccarii car – a revolutionary vehicle transforming the transportation market. This car combines the vertical takeoff and landing capabilities of a helicopter with the versatility of a conventional vehicle. It was designed to navigate remote and challenging terrains.

Beyond their work on drones and the Beccarii car, B-TECHNOLOGY offers a wide range of services in product development, from initial design and engineering to CNC milling and 3D printing.

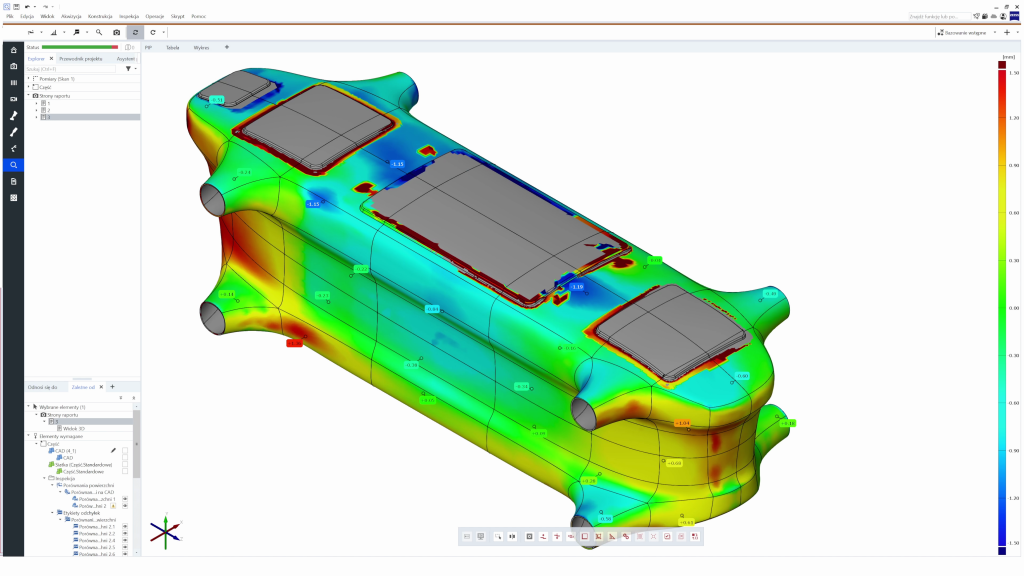

To ensure highest quality standards of their innovations and manufactured parts, B-TECHNOLOGY utilizes ZEISS T-SCAN hawk 2. With the portable and easy-to-use 3D laser scanner, B-TECHNOLOGY can easily control the quality of their produced parts, reverse engineer and validate simulation data against real-world models. ZEISS T-SCAN hawk 2’s ability to quickly deliver metrology-grade data has become an integral part of B-Technology’s work, allowing them to innovate and produce parts while ensuring highest accuracy and quality of their designs.

ZEISS T-SCAN hawk 2 is an invaluable tool for us. It bridges the gap between our simulations and real-world applications, ensuring our designs are both precise and groundbreaking.

Witold Mielniczek - CEO and Founder of B-TECHNOLOGY

Taking innovations to the next level with the Beccarii car

B-TECHNOLOGY is committed to revolutionize the transportation market with their Beccarii car. The unique design promises versatility. It combines the vertical takeoff and landing capabilities of a helicopter with the ability to swim and drive in difficult terrains, reaching places inaccessible to conventional vehicles. The Beccarii car therefore is a great solution for emergency services, exploration, and everyday use.

Challenging conventional transportation

With their innovative idea and commitment to quality, B-TECHNOLOGY is not just building vehicles; they are shaping the future of transportation. Watch our Maker Portrait and find out more:

B-TECHNOLOGY: Controlling quality of drones

Are you ready for exciting insights into the future of transportation? In our new Maker Portrait, our customer B-TECHNOLOGY in Poland tells us all about the development of state-of-the-art drones, both for security operations and for locomotion. The 3D scanner T-SCAN hawk 2 is an important part of quality control here for maximum safety on land, on the water and in the air.

Want to learn more about B-TECHNOLOGY? Visit https://b-technology.eu/

Just take it and make it

3D scanning for high performance seat belts

Take a look behind the scenes at one of the world’s best-known seat belt manufacturers – Sabelt. We explain how 3D scanning is used in product development and quality assurance to ensure maximum safety on the road.

How to create a CAD in ZEISS INSPECT

With the latest software release of 2023 come a variety of new and helpful features for 3D scanning. For example, in ZEISS INSPECT, creating a CAD out of a mesh is now possible via the surfacing function.

3D scanning in the automotive industry

The automotive industry is one of the most competitive fields in the world, under constant pressure to improve quality, cut costs, and boost efficiency. One technology that has proven to be a valuable tool in achieving these goals is 3D scanning. In this article, we look at how and why 3D scanning is used for quality control in the automotive sector and the advantages it offers.