Training for the win!

We here at ZEISS are passionate about excellence, both in our products and our customer service. And what is a great product without knowing how to use it? Which is why we invest in training opportunities tailored to your needs!

Whether you are an experienced engineer or totally new to the world of production and quality control, our trainings teach everything from fundamentals to advanced, industry-specific applications. With every product comes a dedicated education path to help you level up and optimize your workflows. All this is at your fingertips with the ZEISS Quality Suite! Simply access the ZEISS Quality Training Center and discover our many eLearnings or book a classroom training near you!

But there is more! To learn more on our software products, we have, next to our getting started videos, short video training tutorials for you – designed by our training development team and available on YouTube and in the ZEISS Quality Tech Guide. Here we want to introduce our new video series for ZEISS Reverse Engineering.

What’s ZEISS Reverse Engineering?

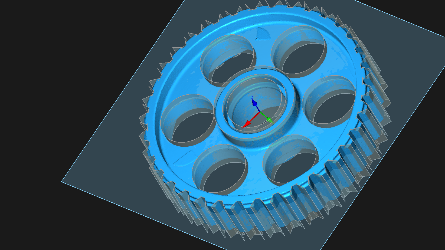

It is a powerful software that allows you to create CAD models based on your 3D scans.

CAD models are an essential part of creating, innovating, and inspecting parts. But they are not always readily available. With ZEISS Reverse Engineering you can take matters into your own hands!

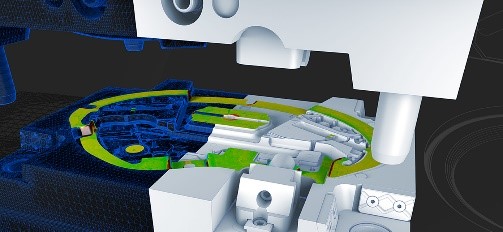

Use your scan data to create a CAD that suits your needs. Whether that is an automated one-click solution for organically shaped parts, an approximation-based approach for rapid prototyping or hybrid modelling, where you combine standard geometries and freeform surfaces. In addition, ZEISS Reverse Engineering supports production- and functional-oriented reconstruction as well as tool correction.

From zero to ZEISS Reverse Engineering hero

Is ZEISS Reverse Engineering the right tool for you? Then let us show you how to use it! The free training tutorials are available on YouTube and in the ZEISS Quality Tech Guide. We start off with a detailed tour of the user interface to get to know the software. Then we explore some of the key functions of ZEISS Reverse Engineering:

Automatic mesh-based surface creation

A quick and easy way to create CAD models that are very close to your scan data.

Surface Approximation to Points

A versatile approach to reconstruct freeform surfaces based on different starting geometries (e.g. planes, cylinders, etc.). Well-suited to rapid prototyping because it offers a balance between customization and simplicity with its range of parameters and optimized algorithms.

Hybrid Modelling

An approach that uses standard geometries and freeform surfaces to reverse engineer parts. A slightly more complex method that provides advantages such as sharp-edged transitions, smaller data size and the potential for optimization in a CAD system. Overall, it offers more control over each step of the reverse engineering process.

What to expect?

Five tutorials cover the software application ZEISS Reverse Engineering step by step. In five to 20 minutes, we tackle different tasks directly in the software. Training data is available for download, so you can follow along or try things on your own later. If you prefer to read or are looking for a summary, check out the ZEISS Quality Tech Guide! The Access Point contains written instructions for each of the workflows as well as additional information.

Who doesn’t use YouTube to find information or solve a problem? I know I do – especially when it comes to new software. And that’s exactly what we wanted to provide with these video tutorials! ZEISS Reverse Engineering is so versatile and it’s fun and easy to use! – Hopefully that comes across.

Stephanie MacKay – Training Developer

What’s next?

For a more comprehensive training, check out the Basic Training ZEISS Reverse Engineering. In two days, it provides everything from a first introduction to the software all the way to advanced approaches, such as the production- and functional-oriented reconstruction.

Besides reverse engineering, ZEISS Reverse Engineering offers patent-pending tool correction functionalities that can dramatically reduce the number of iterations in mold production and verification. To embark on that journey, check out our training “Tool Correction in ZEISS Reverse Engineering«

Stay tuned, there’s more to come with our new software release in the fall! We have a cool new feature in store for you. And there will be more tutorials and advanced training content to support your future projects!

Tobias Schramm – Product Manager

Watch ZEISS Reverse Engineering in action here:

Our ZEISS Reverse Engineering Getting Started videos

You are just starting with ZEISS Reverse Engineering and want to learn more about the fundamental basics of the software? In 2 – 3 minutes we cover the first steps of reverse engineering.