3D scanning software for creating high-quality 3D models

Along with a 3D scanner, having the right software is crucial for creating 3D data. The free version of ZEISS INSPECT gives you all the basic tools you need to get started. This free 3D scanning software includes the following features:

View & edit projects

Import CAD files (standard formats)

3D digitization of parts & components

Mesh processing

Defect analysis & inspection of 3D data

Report creation

For new users, the free version offers everything needed to get started with 3D scanning. The software simplifies the process of scanning objects and transferring data into the system. For users looking for advanced features – like parametric evaluations, a Python interface, or photorealistic rendering – the Pro version of ZEISS INSPECT offers various apps to extend the software’s capabilities.

Why do I need 3D scanning software?

3D scanning is becoming increasingly popular and widespread. 3D scanners are used in a variety of fields – from medical technology and the automotive industry to additive manufacturing. For example, 3D scanning software can help create models for prosthetics or car body parts. But it’s not just businesses that can create and print practical 3D models; you can do it at home too. You can produce things like brackets, spare parts, or stylish storage boxes. 3D scanning software can even be used to create NFTs and other artwork.

3D scanning software for every application

Different applications call for different features in 3D scanning software. If you’re new to 3D scanning and want to ease into the subject, our free ZEISS INSPECT 3D scanning software has plenty of exciting and essential features to get you started. You can use it to scan objects and create STL files, which can then be used for 3D printing, prototyping, or other applications.

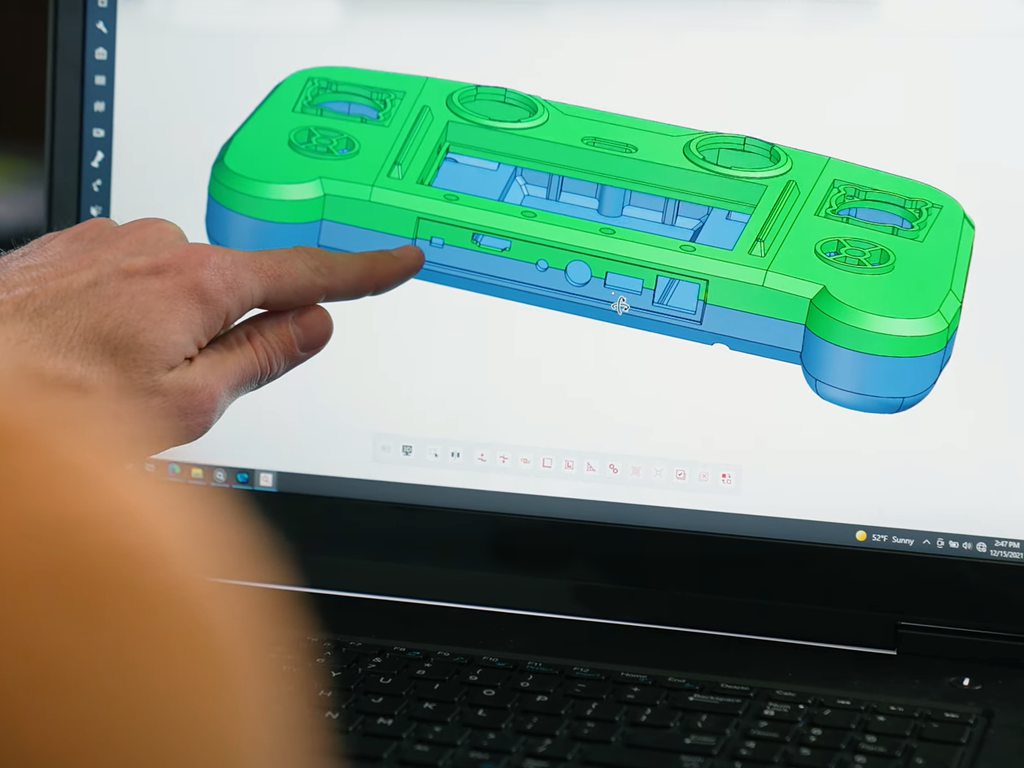

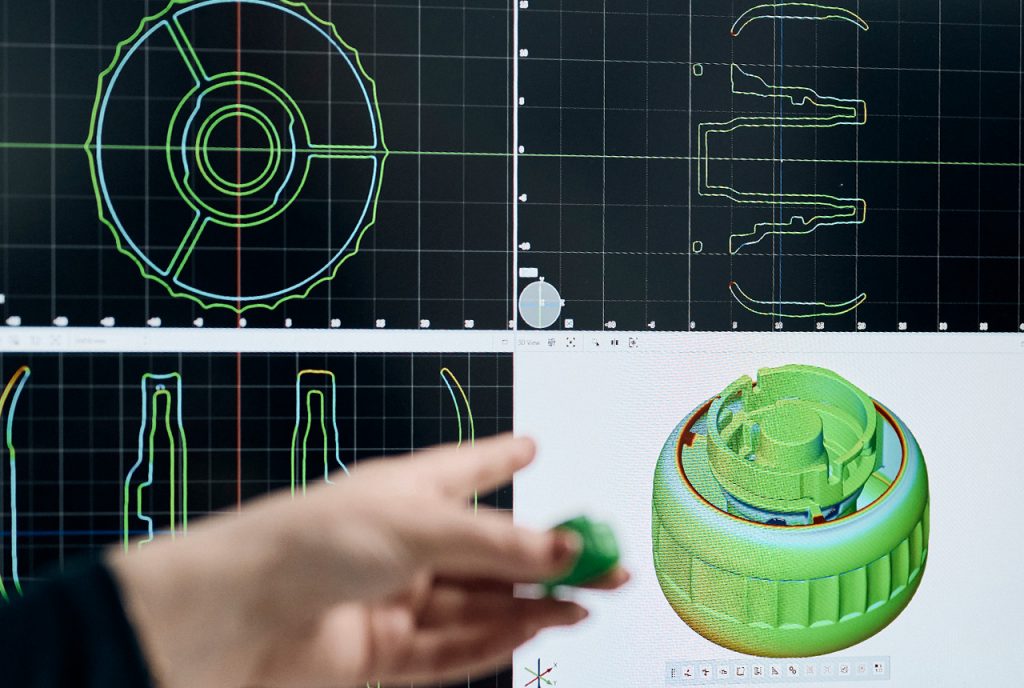

For more advanced projects, you can transfer your scanned data into ZEISS REVERSE ENGINEERING software. This software allows users to create negatives of scanned objects or adjust CAD models as needed. Another useful tool is the De-Warp software app, available in the Pro version of ZEISS INSPECT, which can quickly and easily detect warped areas on plastic parts.

The Pro version of ZEISS INSPECT is designed for professional applications. As the industry standard for 3D inspections and evaluations, it’s a must-have for any quality assurance system. It’s also perfect for efficiently analyzing and visualizing volume data.

ZEISS INSPECT for 3D surface inspection

The Pro version of the ZEISS INSPECT software offers a powerful solution for analyzing and processing high-precision 3D scan data. This 3D scanning software allows users to carry out detailed measurements and quality checks, making it ideal for applications in manufacturing, quality control, and research and development. It can be used to inspect surfaces, verify dimensions, and conduct complex shape analyses. Designed with user-friendliness in mind, it streamlines workflows while ensuring accurate results, and boasts the following features:

- Imports CAD data (standard formats and native files)

- Conducts shape and position analysis (GD&T)

- Processes mesh data

- Generates reports

- Performs digital assembly

- Runs trend analyses

- Carries out parametric inspections

- Extend functionality with apps like Virtual Clamping if needed

ZEISS INSPECT for volume inspections

The ZEISS INSPECT 3D scanning software is specifically designed for analyzing and evaluating industrial CT data. It allows users to visualize and examine the complex internal structures of components in exceptional detail. This 3D scanning solution is ideal for quality control and troubleshooting across various industries, offering non-destructive insights into the internal features of objects.

With ZEISS INSPECT, you get access to the following features:

- Visual inspection of volume data in 2D and 3D

- Defect analysis of parts and components

- Dimensional evaluation of objects

- Volume processing

- Creation of reports, including video documentation

- Automization and customization options

ZEISS REVERSE ENGINEERING

ZEISS REVERSE ENGINEERING is a standalone software that can also be used alongside ZEISS INSPECT. It allows users to quickly and accurately create CAD models from scan data. The software assists with reverse engineering and tool correction, making it possible to create highly precise CAD models, even for complex free-form surfaces. This software is versatile and ideal for a variety of tasks, such as optimizing CAD data for 3D printing and minimizing iterations in mold-making processes.

Download the free trial of ZEISS REVERSE ENGINEERING now and explore these features:

- Import and export of CAD data, meshes, and points

- Mesh editing

- Automatic mesh-based surface creation

- Modeling of high-precision free-form surfaces

- Creation of 2D sketches

- Best-fit/manual creation of 2D and 3D geometric elements

- Target/actual comparisons

- Report creation

Adding a suitable 3D scanner to your 3D software

Are you looking for a scanner for your 3D models? From hand-held laser scanners to stationary 3D scanners, we have the perfect solution for your 3D project. Just click the image and learn more!