HSB: 歴史的蒸気機関車のメンテナンス

あなたの原動力を発見する

Ossiform: 3Dプリント骨インプラントの品質管理

HSB: Maintenance of historic steam locomotives

HSB is the largest service provider for public transportation in eastern Germany. They use the state-of-the-art 3D scanning technology of the ZEISS T-SCAN hawk 2 to ensure that their steam locomotives run non-stop and that their traditional drives are preserved for the future. Accurate 3D models of the machines support the maintenance, repair and overhaul – keeping a part of German history alive in the Harz mountains.

Want to learn more about HSB? Visit https://www.hsb-wr.de/startseite/

HandsOnMetrology: Dedicated to 3D metrology

Welcome to HandsOnMetrology. We are dedicated to 3D scanning and 3D inspection. We want to excite you about 3D metrology. We want to share knowledge. We want to entertain you with stories about makers. All to support your story. Be part of it.

Ossiform: Quality control of 3D printed bone implants

ようこそ

HandsOnMetrologyでは、3Dスキャン測定と3D検査に関する新しい価値を提供します。

最新のセッション

Additive Drives: Development of highly efficient e-motors

At Additive Drives they thrive for highly innovative and efficient e-motors. Their secret? Using 3D printing for individual e-drives based on customers requirements. The 3D scanner ATOS Q offers them quick yet accurate quality assurance of their tools and components during and after the development phase. Want to learn more about Additive Drives? Visit https://www.additive-drives.de/en/

Vudrag Industries: Preserving metal artwork using 3D scanning

Using 3D scanning in the creation of artwork is everyday business at Vudrag Industries. Preserving the metal sculptures, scaling art and making the invisible seen is all possible via a simple 3D scan with ATOS Q and ZEISS T-SCAN hawk 2. Want to learn more about Vudrag Industries? Visit https://vudrag.com/

B-TECHNOLOGY: Controlling quality of drones

Are you ready for exciting insights into the future of transportation? In our new Maker Portrait, our customer B-TECHNOLOGY in Poland tells us all about the development of state-of-the-art drones, both for security operations and for locomotion. The 3D scanner T-SCAN hawk 2 is an important part of quality control here for maximum safety on land, on the water and in the air.

Want to learn more about B-TECHNOLOGY? Visit https://b-technology.eu/

METROTOM 1: How to inspect the inside of medical plastic parts

Plastic parts from the medical industry are often complex assemblies or even transparent and can’t be measured optically or tactilely. Let Juan show you how to use the METROTOM 1 to get all the information with just one scan and even inspect the inside of your parts to guarantee the best functionality.

Do you have any question on our 3D scanners? Contact us via support@HandsOnMetrology.com

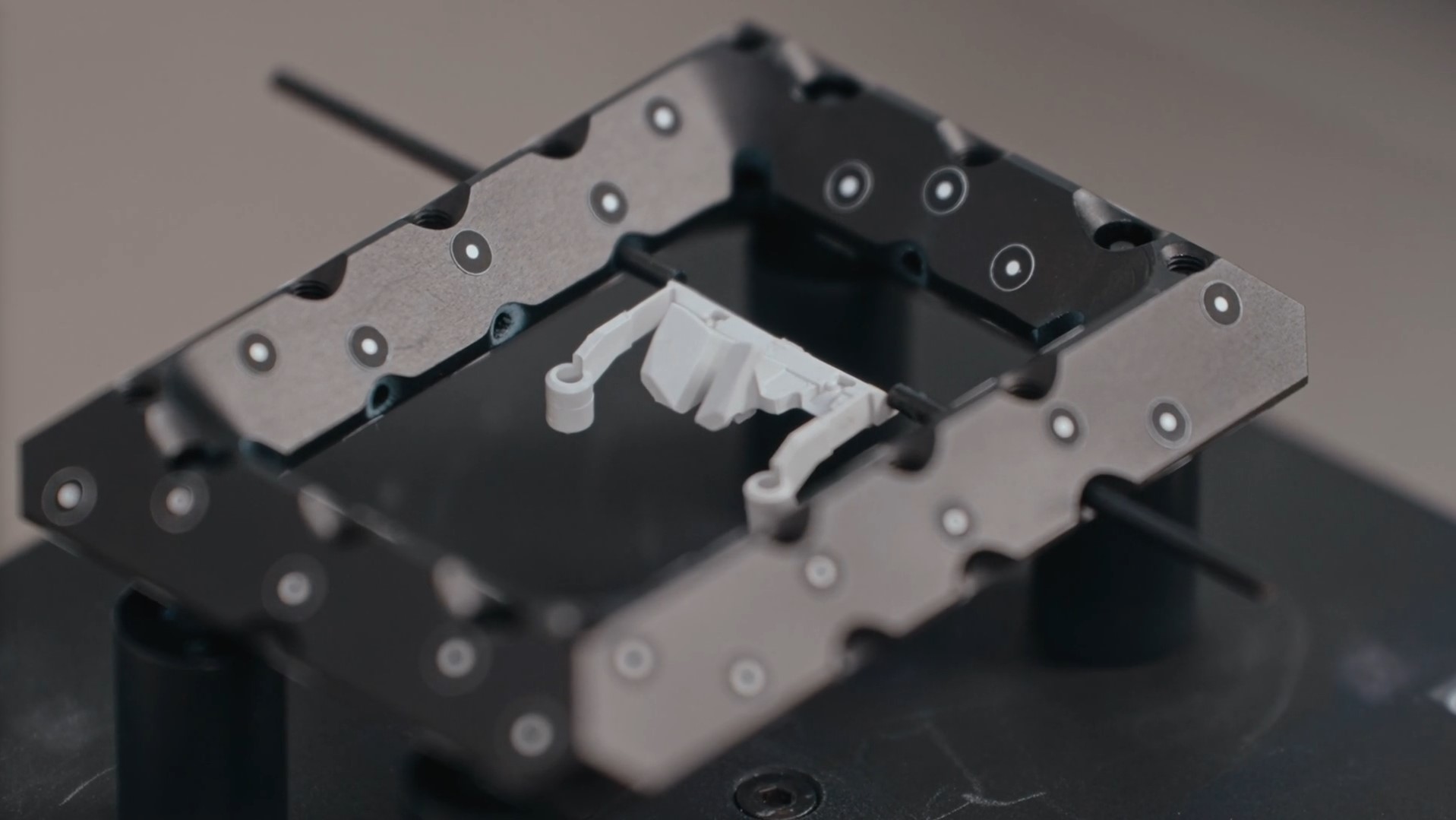

How to scan small parts using compact 3D scanners

3D scanning of small parts and fine details is often a challenge that can take a lot of time. In this How-to, Matthias shows you how you can take the 3D scanning process to a new level with the help of ATOS Q, GOM Scan 1 and the Motorization Kit.

Do you have any question on our 3D scanners? Contact us via support@HandsOnMetrology.com

Büchner: CT technology for plastic manufacturing

Follow the complex injection molding process of plastic parts at our German customer Büchner. The traditional family business relies on intuitive and modern inspection with the 3D scanner METROTOM 1. Powered by CT technology, the company can make meaningful statements about each individual plastic product. Find out more in our Maker Portrait.

Want to learn more about Büchner? Visit https://www.buechner-kunststoffprodukte.de/?lang=en

New videos: One-Minute Insight

Use the Clipping Cube function to get a perfect view

Need to look at a project with a lot of details and obstructed parts? Nanno shows you a trick to get a clear view of just the details you are interested in – by using the Clipping Cube function in ZEISS INSPECT.

All functions shown are available in the current software version.

Have you got any questions about ZEISS INSPECT? Then contact us via email: support@HandsOnMetrology.com

How to save time with Quick GD&T

Get a One Minute Insight from Christine, Carl Zeiss GOM Metrology Braunschweig. She shows you how to save many mouse miles with a single click on “Quick GD&T” to get an extra fast tolerance check. All functions shown are available in the current software version.

Have you got any questions about ZEISS INSPECT? Then contact us via email: support@HandsOnMetrology.com

Data imports from 3rd party scanners

Working with different types of scanners? Well, you only need one software to evaluate your data. In this video, Kai shows you how easy it is to import point cloud data into ZEISS INSPECT, to create a mesh and to start your inspection.

All functions shown are available in the current software version.

Have you got any questions about ZEISS INSPECT? Then contact us via email: support@HandsOnMetrology.com

3Dスキャンの新たな世界へようこそ

HandsOnMetrologyは、3Dスキャンに関するあらゆる知識や情報を提供する新しいプラットフォームです。 ステップバイステップの設定説明から、より高度なチュートリアルや専門家のハックまで。このプラットフォームは、学習のために作られています。 様々な学習リソースをご利用いただけます。 また、優れた3Dスキャンを提供するために必要なサポートを見つけることもできます。 お客様を第一に考えた学習プラットフォームを、ぜひご活用ください。

注目トピック:厳しい測定環境にも対応

製造現場におけるポータブ

ル3Dスキャナー

の使い方

How to measure in production

Small and portable: the ZEISS T-SCAN hawk 2 is made for the use in production. See here how it supports your complete process chain from data collection for reverse engineering, different inspection tasks to the digital assembly of produced parts.

Do you want to find out more about the portable 3D laser scanner T-SCAN hawk 2? Visit HandsOnMetrology.com/sessions

他のセッションを見る

Additive Drives: Development of highly efficient e-motors

At Additive Drives they thrive for highly innovative and efficient e-motors. Their secret? Using 3D printing for individual e-drives based on customers requirements. The 3D scanner ATOS Q offers them quick yet accurate quality assurance of their tools and components during and after the development phase. Want to learn more about Additive Drives? Visit https://www.additive-drives.de/en/

CADskills: Improving patient specific implants

At CADskills it’s all about custom made implant solutions. Based on CT data, the company designs and develops biofunctionalized implantable devices for dysfunctional joints and bones. To further improve the quality control of their products they use ATOS Q. Have a look at the work of our customer in Belgium to get all the details.

Want to learn more about CADskills? Visit https://www.cadskills.be/en/

METROTOM 1: Scanning multiple parts

The 3D scanner ZEISS METROTOM 1 – powered by CT technology – is perfect for scanning multiple parts at once, as it seriously reduces scan times. Interested? Then watch Aysel and John’s tutorial. Learn how to prepare the parts for 3D scanning, discover how to set up the software – and experience its simple, built-in separation tool: for separating out the batch volume into smaller volumes for each individual part.

Have you got any questions on 3D scanning?

Contact us via support@HandsOnMetrology.com

How to 3D scan with the right distance to object

How does satellite mode work and why do you need it

Scanning larger parts can be challenging. We simplified the the process with the new satellite mode of the handheld laser scanner ZEISS T-SCAN hawk 2. It does without coded markers thus preparations are easy and fast. Learn more about the advanced way of photogrammetry here. Got any questions? Contact us via support@HandsOnMetrology.com.

How to use a 3D scanner for dent detection

Looking for a way to speed up and refine your aircraft MRO? Let Roel show you how the ZEISS T-SCAN hawk 2 and the Inspect Software aid in various inspection tasks, like GD&T, CAD comparisons or defect maps. Got any questions on 3D scanning? Contact us via support@HandsOnMetrology.com

ニュースレター登録

HandsOnMetrologyの最新情報をいち早くお届けいたします

お客様に最適な3Dスキャンソリューションをご提案します。

3Dスキャンソリュー ションをお探しです か?

ZEISS INSPECT

品質を視覚化

シンプルで直観的な操作性と包括的な検査機能を備えた、

3D測定データ用検査ソフトウェアです。業界標準としての地位を確立したソフトウェアを、無料でダウンロードし

ていただけます。