Mobile 3D scanning of water pumps

Our 3D scanning partner Midwest Metrology from the U.S. took us to their customer TG Machine. Since 1989, it’s all about the custom machine shop that specializes in CNC Machining, turning, welding and CMM fixturing.

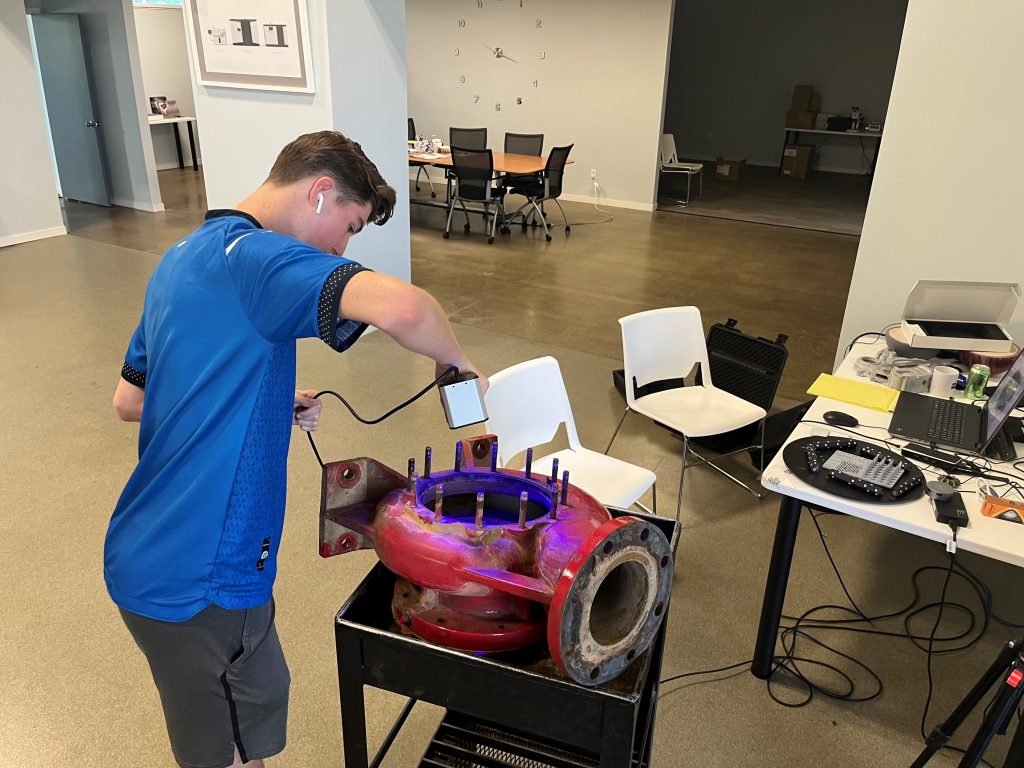

A very important job was given to Midwest Metrology when a large water pump broke. This had been used for dewatering applications in the construction industry. In order to keep the company’s vital processes running, a new pump was needed quickly to match the old one. But the geometries of the object were so complex that hand tools were not sufficient to collect all the part information. This is where the ZEISS T-SCAN hawk 2 unleashed its full potential. Portability was a must since some areas were hard to reach. The hand-held scanner performed with maximum flexibility and made data acquisition intuitive and easy. It perfectly adapted to the user’s unique workflow and hand movement. Furthermore, T-SCAN hawk 2 was able to collect precise data of intricated details as well as larger plain surfaces.

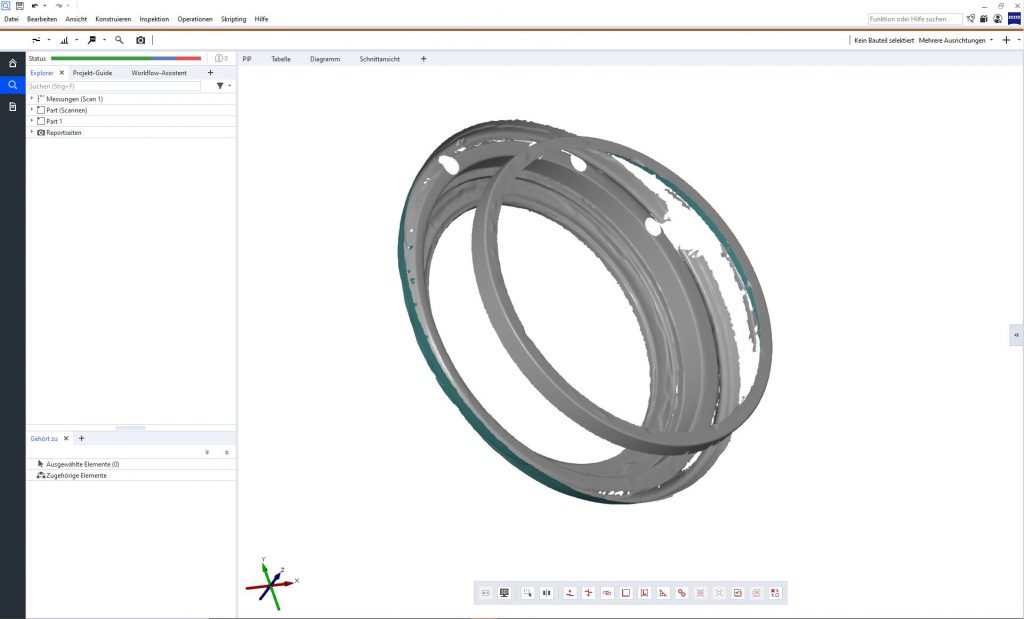

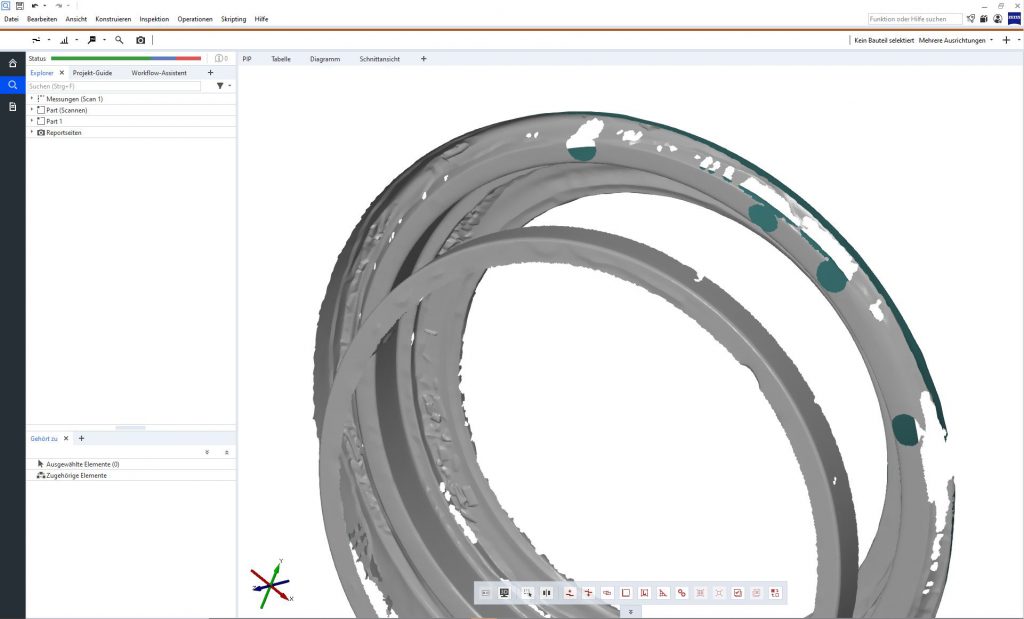

3D data of complex casted parts

Midwest Metrology chose the pro version of the inspection software to get even more out of their scan data. With the collected part information, a CAD was generated quickly and easily. It can now be used for the rebuild of the water pump.

Try T-SCAN hawk 2

Contact your local dealer for more information.