What is reverse engineering?

Reverse engineering involves analyzing an object, machine, or product to get an understanding of its design, form, functions, and parts. The method is commonly used in product development, manufacturing, and maintenance, extracting data from physical objects or systems and converting it into digital formats.

Reverse engineering is particularly useful for gaining a thorough understanding of a product or machine. By dissecting and reconstructing products or parts, weaknesses and design flaws can be identified and rectified. This also makes it quicker and more cost-effective to repair or reconstruct products.

Reverse engineering is commonly used in companies to analyze improve their own products, or update older ones. Reverse engineering can also accelerate the product development process by speeding up the creation and optimization of prototypes.

Various methods are used in reverse engineering, including 3D scans, which capture the structure and geometry of an object. Additionally, CAD models can convert physical objects into digital format for analysis.

How does reverse engineering work?

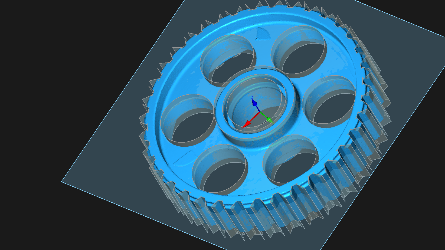

The first step to reconstruct surface data into design data is to use a 3D scanner. They allow for non-contact and full-field scanning of entire part surfaces. Using millions of measuring points, the ZEISS INSPECT software computes the 3D coordinates by creating a high-resolution point cloud, the so-called STL mesh.

This polygon mesh forms the basis for creating a CAD model as part of the surface reconstruction. To convert the scan data into mathematically described curves (splines), freeform surfaces (NURBS surfaces), standard geometries (primitives) or solids, the data can be exported from the ZEISS INSPECT software as an STL mesh or ASCII point cloud.

The actual conversion of the scan data into a CAD surface model requires specific software packages, such as Geomagic, Tebis and ZEISS REVERSE ENGINEERING. Some CAD programs now also have modules for surface reconstruction.

To ensure that the CAD surfaces actually match the scan data, this newly created surface data can be reimported into the ZEISS software for validation. The ZEISS software can then be used to compute the deviations between the new CAD data and the scan model for an accuracy analysis and to visualize them in the form of a color deviation representation.

Reverse engineering software

Reverse engineering software is widely used in industries such as automotive, aerospace and manufacturing. There are numerous software tools available for reverse engineering in these fields. Each method typically has dedicated software or tools included in a comprehensive software package, such as CAD software, 3D scanning software, image processing software, and source code analysis tools.

ZEISS has developed its own reverse engineering software called ZEISS REVERSE ENGINEERING. Built upon a core surface reconstruction module, this software offers two additional functionalities: Tool correction and volume calculation. This flexibility allows users to choose the option that best fits their needs.

Examples of reverse engineering

Reverse engineering is used in various sectors and industries to analyze, enhance, or replicate products, systems, and parts.

Here are some practical examples and applications of reverse engineering across various industries:

• In the automotive sector, reverse engineering is used to analyze and refine the geometry of existing components. For example, 3D scans of car parts can help to enhance car aerodynamics or produce spare parts for discontinued models where originals parts are no longer available.

• Reverse engineering is used in the manufacturing industry to create prototypes and streamline production processes. This involves using 3D scans and CAD models to optimize the production of components or products and identify defects or weak points.

• In the aerospace sector, reverse engineering is used for analyzing and refining intricate components and systems. 3D scans and CAD models can increase aircraft or spacecraft safety and make maintenance work easier by flagging weaknesses and defects.

• Reverse engineering is used in software development to analyze program functionality and identify bugs and errors in the source code. Source code analysis tools can help to increase program security and rectify functional errors.

• Reverse engineering is also used in connection with new technologies. Digitized 3D surface models serve as the basis for 3D printing or as data input for VR applications, for example.

Advantages and disadvantages of reverse engineering

Reverse engineering offers several advantages, including time savings, cost reduction, and enhanced product quality.

Here are some key benefits:

Time savings

By analyzing and optimizing existing products or components, reverse engineering can significantly reduce the time required for product development and manufacturing.

Cost reduction

By scrutinizing and optimizing existing products or components, reverse engineering cuts down on product development and production costs.

Enhanced product quality

Reverse engineering can help to improve product quality by analyzing and optimizing existing products or components.

However, reverse engineering comes with certain challenges, particularly for those less familiar with the subject and relevant software. These include potential reconstruction errors or inaccurate data.

Here are some of the main drawbacks:

Complexity

Reverse engineering can be highly complex, particularly when it comes to intricate components or systems. It often requires specialized knowledge and skills to analyze and interpret data accurately.

Inaccurate data

Inaccuracies can arise if methods and procedures are not correctly applied, or if the collected data lacks precision, e.g. with calipers.

Reconstruction errors

Inaccurate data or flawed analysis may lead to reconstruction errors, undermining the reliability of reverse engineering.

ZEISS REVERSE ENGINEERING simplifies this process with its user-friendly interface, guiding users through each step of the software application. This minimizes operating errors and potential inaccuracies from the start. Additionally, ZEISS offers comprehensive training courses to equip users with the necessary skills to operate the software effectively within just a few days.

Reverse engineering in business

Companies use reverse engineering in various ways to enhance their products or create new ones. Here are some of the most common applications of reverse engineering in business:

Improving products

Reverse engineering can help to improve existing products by analyzing and optimizing their components or systems.

Repair & maintenance

Reverse engineering can help in repairing or servicing damaged components or systems by creating exact replicas.

Product development

Reverse engineering serves as a foundation for developing new products, using existing products or components as starting points.

In addition to these benefits, reverse engineering offers another significant advantage:

Protection of intellectual property

Companies can safeguard their intellectual property by analyzing existing products or components and implementing protective measures as needed.

With ZEISS REVERSE ENGINEERING, you can harness these benefits and take your company to the next level.

Increasing quality assurance with reverse engineering

Reverse engineering is an important process that can help enhance products and processes and develop new products. Techniques like 3D scanning allow for the creation of exact replicas of components and systems, and specialized software supports these reverse engineering efforts.

There are many advantages to reverse engineering, including enhanced product quality, cost reduction, and time savings. Companies use reverse engineering in various ways to improve existing products or develop new ones.

In summary, reverse engineering is a key method for optimizing and improving products and processes. Businesses should consider it a valuable tool and utilize its various methods and processes to leverage their full potential.